Ensuring pallet stability is a vital part of safe and efficient shipping and logistics. Goods that are properly secured are less likely to fall or get damaged, which in turn reduces the likelihood of delays or increased costs.

Therefore, maintaining proper pallet stability is crucial for manufacturers, especially for those involved in high-volume shipping. In this blog, we share best practices for securing a stable load and explain why investing in automation can help deliver consistency every time.

How to ensure pallet stability

A robust stacking strategy is key to ensuring a secure load. Think about:

1. Distributing weight evenly

Place heavier items at the bottom of the pallet to create a strong, stable base and reduce the chances of tipping or imbalance. Each layer of products should have a consistent weight distribution to prevent pressure points that could compromise the pallet’s integrity. Even weight distribution across the surface of the pallet ensures that it remains stable during both storage and transport.

2. Stacking boxes tightly

Gaps between boxes can cause products to shift, impacting stability and increasing the likelihood of product damage. Tight stacking prevents movement within the pallet and keeps the load secure. If gaps are unavoidable, such as between irregular-sized items, use filler materials to fill any empty spaces.

3. Interlocking patterns for strength

Interlocking or bricklaying stacking patterns are highly effective in distributing weight evenly and therefore enhancing pallet stability. By alternating the direction of each layer, you create a more solid structure that resists shifting. This technique ensures the pallets can bear more weight without compromising stability, and it also makes the pallet easier to store and stack efficiently.

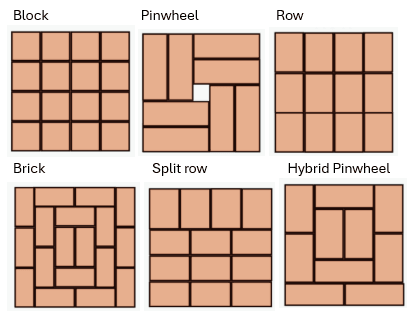

Six common load-securing patterns are:

- Block: Boxes are aligned in a simple grid, layer by layer. This works well with uniform box sizes.

- Pinwheel: Layers alternate between horizontal and vertical blocks, “weaving” around a central void. This interlocks each layer, improving stability under sideways force.

- Row: All boxes face the same direction in each layer. While straightforward, it can be less stable if not combined with stretch wrap.

- Brick: Boxes are “staggered” like bricks in a wall. Each box rests partly on two below, so weight is spread more evenly.

- Split row: Each layer is divided into two or more rows. Rows alternate orientation between layers to prevent long, unbroken seams of weakness.

- Hybrid pinwheel: A combination of pinwheel at the core with block layers around it. This provides both interlocking strength and load‐bearing support.

4. Top and centre loading

The load should be properly centred, with products kept within the perimeter of the pallet without overhanging. This prevents instability, especially when pallets are stacked, by ensuring that no single part of the pallet carries too much weight.

5. Wrapping techniques

Once a pallet is stacked, use high-quality stretch film, either hand-held or machine-applied, to wrap it tightly from bottom to top and lock the load in place. Ensuring at least three full revolutions around the base and for uneven loads or mixed sizes, consider a spiral-wrap pattern that overlaps layers for uniform tension. Corner boards or edge protectors can be added before wrapping to reinforce corners and prevent film tearing.

Automated palletising for precision and consistency

Automatic palletisers use advanced robotics to stack products with high precision, eliminating the variability of manual processes and ensuring that every pallet meets optimal load stability standards. Many feature pattern forming software, which automatically calculates the best way to stack products for maximum stability by analysing the size and shape of each item.

All of our automatic palletisers can also be specified with an integrated stretch‐wrapping module. This maintains consistent film tension and overlap on every pallet, guaranteeing a uniform, secure wrap to resist movement and protect products.

Faster and safer operations

Automation not only improves pallet stability but also accelerates the loading process. Automated palletising systems can work continuously, 24/7, without the fatigue that affects manual labour. This not only improves productivity but also reduces the risk of accidents and injuries caused by repetitive manual stacking.

Find out more about our automated palletising systems and how they can improve your operations here.