PALpack Limited

PALpack are the UK's leading experts in palletising systems, and we are the UK agents for top of the range machinery supplied by European manufacturers.

Industries We Work In

Food

Food

The fast pace world of food production means there’s an ever increasing demand on process and packaging. With over 25 years of experience in the industry, we have a track record in the installation of palletisers to help get the job done.

Beverage

Beverage

When it comes to bottles and jars, we are experts in the palletising and de-palletising. Whether this is a medium or high-speed palletiser or a pick and place system, we have solutions to load, unload and feed into the bottling halls.

Pet Food

Pet Food

The pet food market in the UK is worth approximately £4 billion, and is growing. The requirements of this demanding industry are very similar to food and beverage and we have an in-depth expertise in the palletising these types of goods for efficient handling.

Aggregates & Grains

Aggregates & Grains

Aggregates and grains are notoriously difficult to palletise and often production facilities use manual labour to carry out the process. However, we have partnered with Europack who have mastered sack palletising perfect for this specific application.

Chemicals

Chemicals

Moving, packing and preparing chemicals for shipping, needs to be as safe as possible. Liquids are normally dispatched in drums, and solids in sacks, cartons and or bails. All of which can be problematic when palletising. Our solutions can be used to safeguard manual handlers.

Pharmaceuticals

Pharmaceuticals

Our partners are specialists in the field of pharma machinery, and we work with them to offer a full turnkey solution. From processing, through to blister packaging, cartoning and palletising, with track and trace functionality for peace of mind.

Why Choose PALpack

PALpack work with our UK clients to offer practical, technical advice when there is a need to automate palletising.

- Experts in automation, robotics and engineering project management

- Over thirty years' experience in the field

- PALpack engineers are hands on throughout FATs and SATs

- All our installations are offered with after sales service

- We offer a UK based spares and service contract

Dave Wood

The European leader in cartesian packing and palletisation robotics

The UK's official agent

for Spider Robots

Formed over 30 years ago, Spider Robots is one of Europe’s leading suppliers of palletisers. PALpack is proud to be the UK’s official agent for Spider.

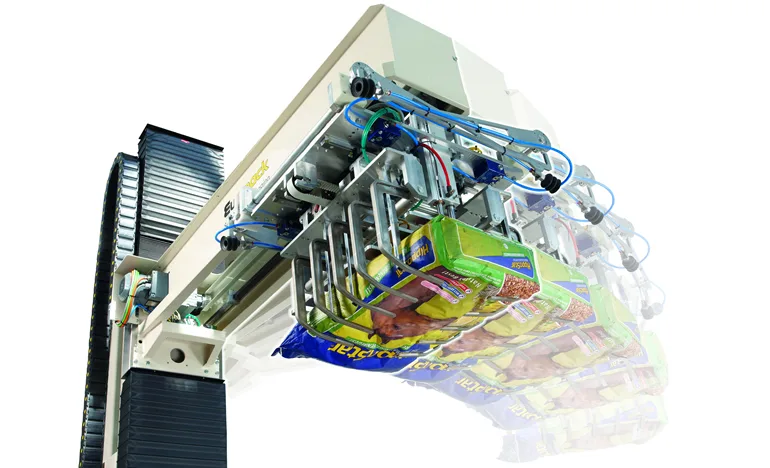

As one division of the Montech Group, Spider Robots focuses on offering high-end flexible palletising solutions. Spider’s modular palletiser has many impressive features, which makes these machines easy to use, very flexible, and compact.

Check Out Our Work Process

Make an Enquiry

Develop a Scope of Work

Let’s Make it Happen

Featured Products

Palletisers

The palletiser automates the stacking process that can otherwise be labour intensive and expensive, putting undue stress on workers. There are many types of palletisers used today, designed to be configured alongside the other production line facilities. Palletising is indeed a critical part of the manufacturing process.

Robot Palletisers

Robot palletisers are becoming an increasingly popular application. They are capable of assembling mixed pallets as well as palletising different items simultaneously. They are cost effective to install, but robotic palletisers typically are slow speed and low output.

De-Palletisers

De-palletisers are machines that unload items from the pallets. Using de-palletisers can bring costs and time savings, and also relieve workers from undue physical stress. Palletisers and de-palletisers can play a crucial role in the production process. They are used to transport parts from one line to another during manufacturing.

Handling Systems

Handling systems will be used for handling and the keeping of packages before they arrive at the palletiser. Conveyor systems will be designed according to the typology, plant layout, and also the types of items to be palletised.

Sack Palletising

Sack Palletisers can be configured to process a wide range of sacks and bags. These types of palletisers can help to compress and secure the layers of sacks onto the pallet.

Sack Filling

PALpack offers automation solutions for sack filling, weighing and sealing at high speed. We work with trusted European partners who have decades of experience in improving production lines and specialise in reliable, high speed technology.

What Our Customers Are Saying

Since our machine was installed last February our line efficiency has improved dramatically with little or no downtime recorded for technical issues and their after sales service is the best we have had from anyone in the 16 years of bottling production. What I like about Dave is that he’s not a salesman but someone who has designed and built machines and has a wealth of experience in this field. He won’t push something on you if it’s not right for your business. I would thoroughly recommend Dave and PALpack to anyone looking for some automatic palletisation on their production lines.

PALpack installed our first purpose-built palletiser. It was our first venture into this level of automation and 10 months later we have just completed our first filling line. We are already seeing some of the required results in terms of reduced manning and everyone is impressed with the quality of the installation and the resulting pallet appearance. I would thoroughly recommend David and PALpack as partners in palletisation particularly for a business that is unfamiliar with this degree of automation.

In 2018 we ordered a large palletising system from Lita Palletisers in Italy. Our palletiser was also supplied with an integrated Tosa pallet wrapper. I felt confident working with Palpack because their MD Dave Wood is someone I have known for a number of years. Palpack’s approach to capital equipment sales, is one of a technical nature and they spent a lot of time measuring our shop floor, ensuring that the new equipment fitted into, what was a tight space. The machine was delivered on a Friday lunchtime, Palpacks engineers were on site waiting for the machine and by Sunday evening the whole system was installed, wired up and ready for commissioning by Lita Technicians. By Tuesday the machine was up and running and in full production. Since installation Palpack’s back up and support has been exceptionally good and we are happy to work with Palpack again and we are currently working on a second installation using them.