Sack Filling

PALpack offers several automation solutions for sack filling, weighing and sealing at high speed. We work with trusted European partners who have decades of experience in improving production lines and specialise in reliable, high speed technology.

Custom automatic and semi-automatic sack filling systems can integrate additional devices such as scales, vibrating feeders, conveyors and printing. Bag sealing technology will be chosen in accordance with the bag type and product, whether it’s grains, pellets or aggregates.

Sack-filling machinery can also integrate with other automation solutions such as conveyors or sack palletising.

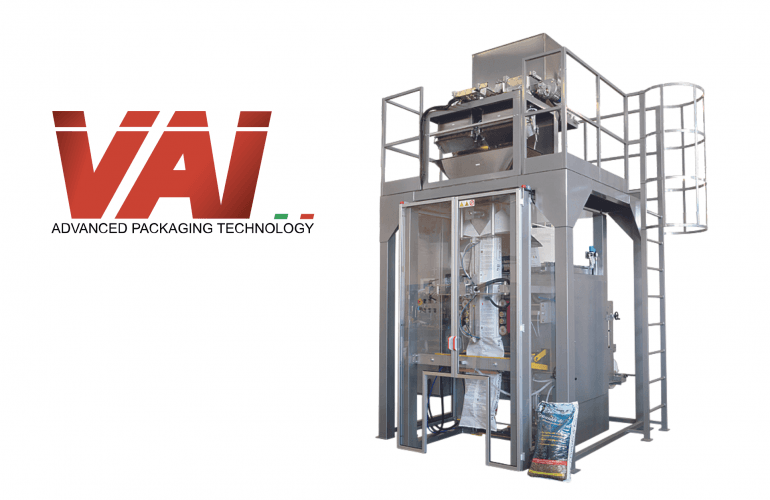

Vertical Form Fill and Seal Machine from VAI

VFFS (vertical form fill and seal) packing machines bag grains, pellets and aggregates in medium to large sacks and then seal them ready for palletising and transportation. Automatic or semi-automatic systems have the capacity to fill up to 1500 bags per hour.

Products

Sack filling and packaging can be used for both food and non-food products, including:

- Flour

- Sugar

- Salt

- Pasta

- Biscuits

- Pellets

- Cement

- Mortar

- Pet food

- Animal feed

- Seeds