Palletisers

The palletiser automates the stacking process that can otherwise be labour intensive and expensive, putting undue stress on workers. There are many types of palletisers used today, designed to be configured alongside the other production line facilities. Palletising is indeed a critical part of the manufacturing process.

Robot Palletisers

Robot palletisers are becoming an increasingly popular application. They are capable of assembling mixed pallets as well as palletising different items simultaneously. They are cost effective to install, but robotic palletisers typically are slow speed and low output.

De-Palletisers

De-palletisers are machines that unload items from the pallets. Using de-palletisers can bring costs and time savings, and also relieve workers from undue physical stress. Palletisers and de-palletisers can play a crucial role in the production process. They are used to transport parts from one line to another during manufacturing.

Handling Systems

Handling systems will be used for handling and the keeping of packages before they arrive at the palletiser. Conveyor systems will be designed according to the typology, plant layout, and also the types of items to be palletised.

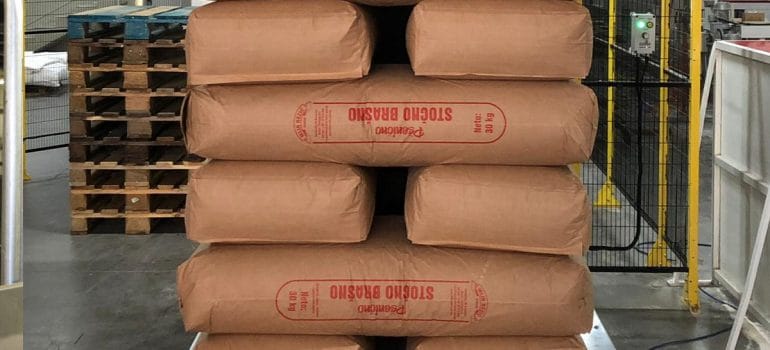

Sack Palletising

Sack Palletisers can be configured to process a wide range of sacks and bags. These types of palletisers can help to compress and secure the layers of sacks onto the pallet.

Sack Filling

PALpack offers automation solutions for sack filling, weighing and sealing at high speed. We work with trusted European partners who have decades of experience in improving production lines and specialise in reliable, high speed technology.