Maximising pallet stability: 5 techniques for optimal load securing

Ensuring pallet stability is a vital part of safe and efficient shipping and logistics. Goods that are properly secured are less likely to fall or get damaged, which in turn reduces the likelihood of delays or increased costs. Therefore, maintaining proper pallet stability is crucial for manufacturers, especially for those involved in high-volume shipping. In this blog, we share best practices for securing a stable load and explain why investing in automation can help deliver consistency every time.

The benefits of automated depalletising for high-volume manufacturing

Automated depalletising plays a crucial part in streamlining production processes. But what exactly is depalletising, and why should manufacturers consider automating the process? In this blog, we’ll explain just what’s involved and explore some of the benefits in high-volume manufacturing.

Introducing Spider Robots: PALpack’s newest palletising partner

Spider Robots has been building automatic packing and palletising lines for over 30 years, and are one of Europe’s leading suppliers of palletisers. PALpack is proud to announce that we are the UK’s official agent for Spider Robots.

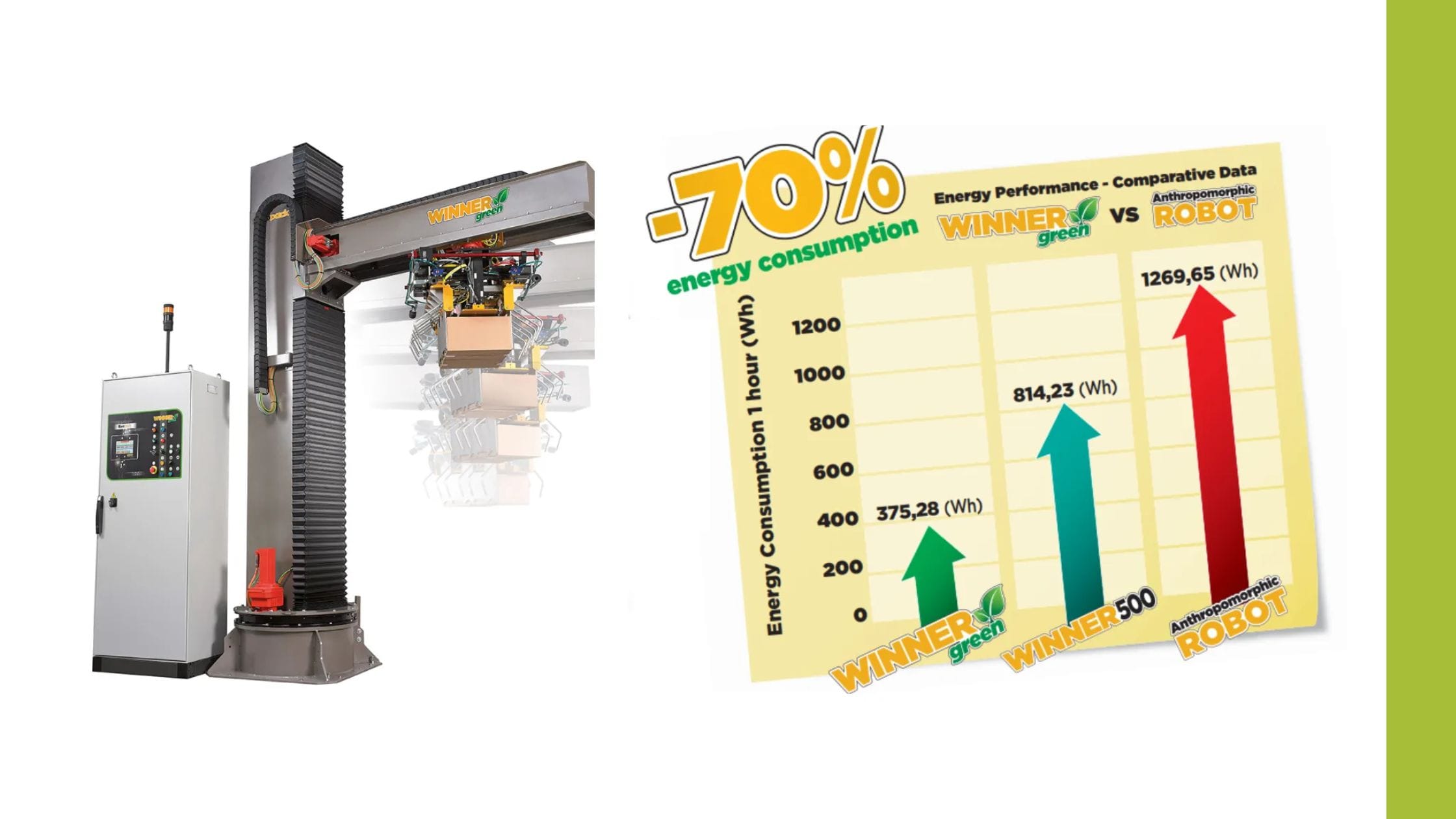

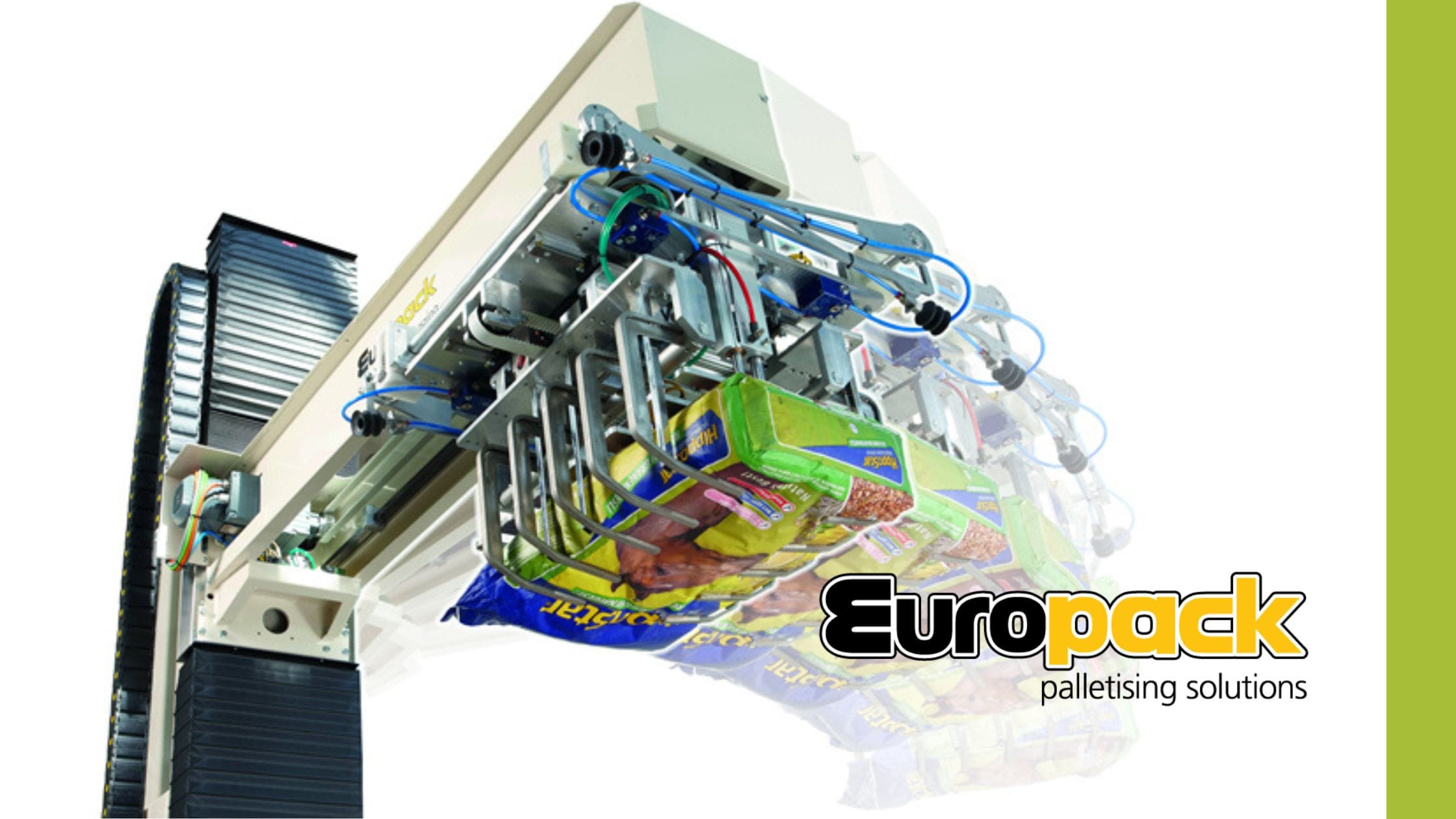

Europack: Pioneers in European Automation

The needs of modern manufacturers are evolving: more competition, higher customer expectations and rising costs mean they’re under increasing pressure to improve throughput and enhance efficiency.

Why customise your automation solution?

We’ve covered the benefits of automation before, but now manufacturers seeking enhanced efficiency and lower costs are taking things a step further with customised systems. Custom automation solutions are tailored to individual operations. Designed to meet the unique needs and challenges of specific businesses, they offer greater flexibility, improve quality and align with production demands, giving businesses competing in an increasingly demanding landscape a significant edge.

Solving common end-of-line bottlenecks: A troubleshooting guide

For many manufacturers, time is money. Faster operation and streamlined production result in greater throughput and better manufacturing efficiency, while interruptions cause delays and increase costs.

New talent accelerates automation across Scotland

It’s been a busy year so far at PALpack, with two new additions to the business. Last month, we announced we were working with secondary packaging specialists Gampack Group, and now we’re delighted to announce the appointment of our first regional sales manager.

Working with Gampack to maximise efficiency

Manufacturers looking to maximise efficiency must embrace automation at every stage of their operations, from product handling to final packing. At PALpack, we’re working with a new partner to enable exactly that. Gampack Group provides a wide range of packaging machinery, combining industry expertise with cutting-edge technology to create secondary packaging solutions that are not only functional but also sustainable.