A gantry palletiser is just one of several different types of palletiser available to manufacturers looking to automate their production line and help speed up the sorting, transferring and stacking of goods onto a pallet.

Gantry palletisers (also referred to as cartesian palletisers) feature a gantry or structural beam and axes which are used to pick and place the items. Usually, one or two (sometimes more) products are collated on an infeed conveyor and collected with a gripping device, which then places them onto the pallet. One of the advantages of a gantry palletiser is that products can be moved in four directions to form complex pallet patterns.

Systems can range from simple pick and place functions to more extensive operations, but production rates are typically less than 20 packs per minute. Due to this medium paced speed and lower output, gantry palletisers are most frequently used for handling heavy products – they’re a good choice for larger sacks as they can be configured to carry bags weighing hundreds of pounds.

However, a gantry palletiser can be used for most product types, including trays, cases, loose trays (no shrink wrap) and large containers, such as jerry cans or canisters. And whereas layer palletisers are very fast, in comparison, these palletisers are restricted, in that they can usually only be used for one product at a time. Gantry palletisers can have more than one infeed conveyor, and palletise two different products at the same time.

Exploring palletising

Palletising is a critical part of the manufacturing process but manually filling pallets is time-consuming, labour-intensive and monotonous work – and comes with the risk of injury associated with heavy lifting and repetitive movements. Therefore, automating this part of your production line by adding a palletiser is a good way of improving the speed and efficiency of the line and reducing absences due to injury or low morale.

There are two other types of palletisers available, layer and robotic, and both of these are better suited to medium-to-high-speed production lines.

Layer palletisers

Layer palletisers are much quicker than robotic or gantry palletisers. A full layer of products or boxes is collated onto a table and then placed onto the pallet, so speeds of up to 60 packs per minute can be achieved. Packs that may usually be difficult to handle are much easier to manoeuvre on these machines because no gripper is required to pick and move the items. This can make them a better solution for some products than a gantry palletiser where the gripper is a possible restriction with more difficult products.

Layer palletisers can also be used to process a wide range of sacks and bags, compressing and securing layers of sacks onto the pallet.

Robotic palletisers

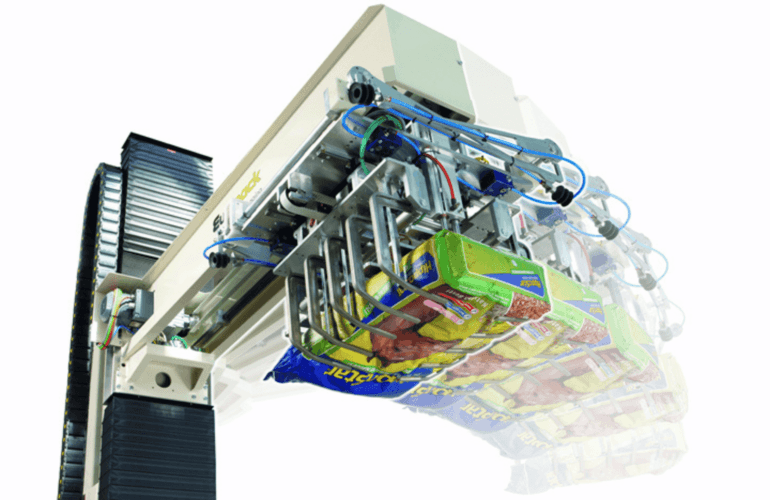

Robotic palletisers are becoming increasingly popular due to their relatively small footprint and the flexibility to change the layer pattern. Packages are picked up by a gripper, clamp, magnet or combination of devices and unlike the layer palletisers, these machines can accept multiple production lines as well as palletising different items simultaneously. The disadvantages of robotic palletisers are the slower speeds.

World-renowned manufacturer

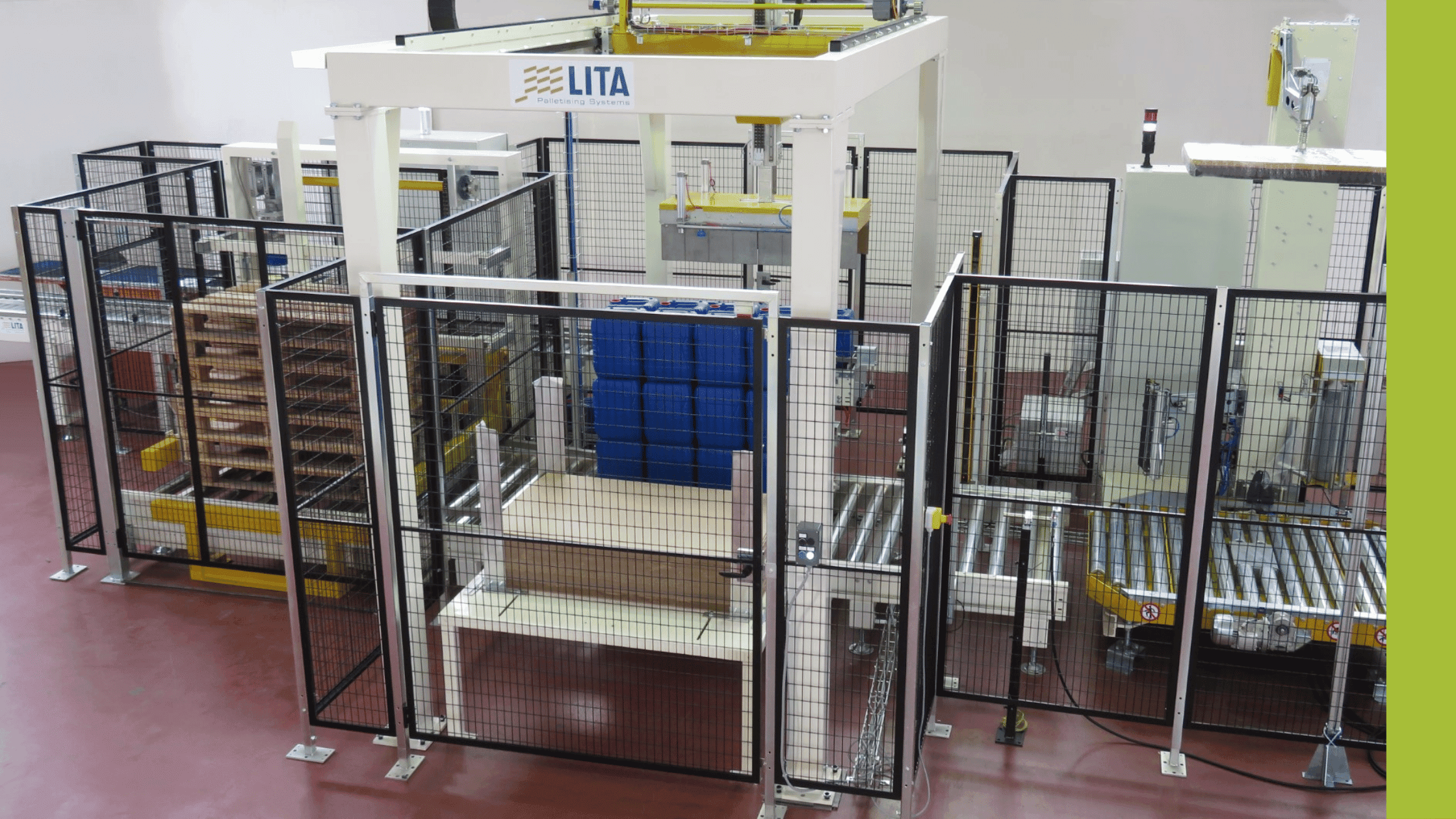

Lita is one of the world’s oldest manufacturers of automated palletising systems and produces a wide range of machines suitable for different products and environments. Since 1962 the firm has been the first choice for many companies due to its exceptional design and build standards and hundreds of machines have been installed around the world in sectors varying from food to cosmetics.

- The Jolly is an example of a gantry-style cartesian palletiser. Suitable for handling RSC cases and shrink-wrapped packs with a maximum payload of 30kg, its lightweight aluminium axis carriages make the machine agile, fast and power-efficient. Several gripper heads are available for handling different products and pack infeed conveyors can be designed for either single or multiple picking.

- The Presto is an automatic low-level infeed layer type palletiser used in medium-to-high-speed applications. Suitable for handling RSC cases and shrink-wrapped packs, it features automatic changeover of products and has an output of 42 packs per minute from a single infeed or 65 packs per minute from a twin infeed.

- The Logico is Lita’s robotic palletiser, which can be designed to accommodate specific production speeds, existing lines or space restrictions. Different gripper heads are available with either side clamps or a vacuum function and infeed conveyors can be designed for single or multiple picking.

Choosing the right palletiser

Whatever sector you operate in, adding a palletiser to your production line brings efficiency, financial and time savings. Whether your aim is to reduce heavy lifting, speed up the process of palletising multiple lines at the same time or load difficult-to-handle packages more easily, the wide range of palletisers available from PALpack means there’s sure to be one that will help to improve your processes.