Robotic palletisers automate the stacking of products onto pallets and can handle mixed pallets, one of many options for end of line packaging automation. What are the advantages of commissioning a rotating beam palletiser from Europack?

Compact footprint

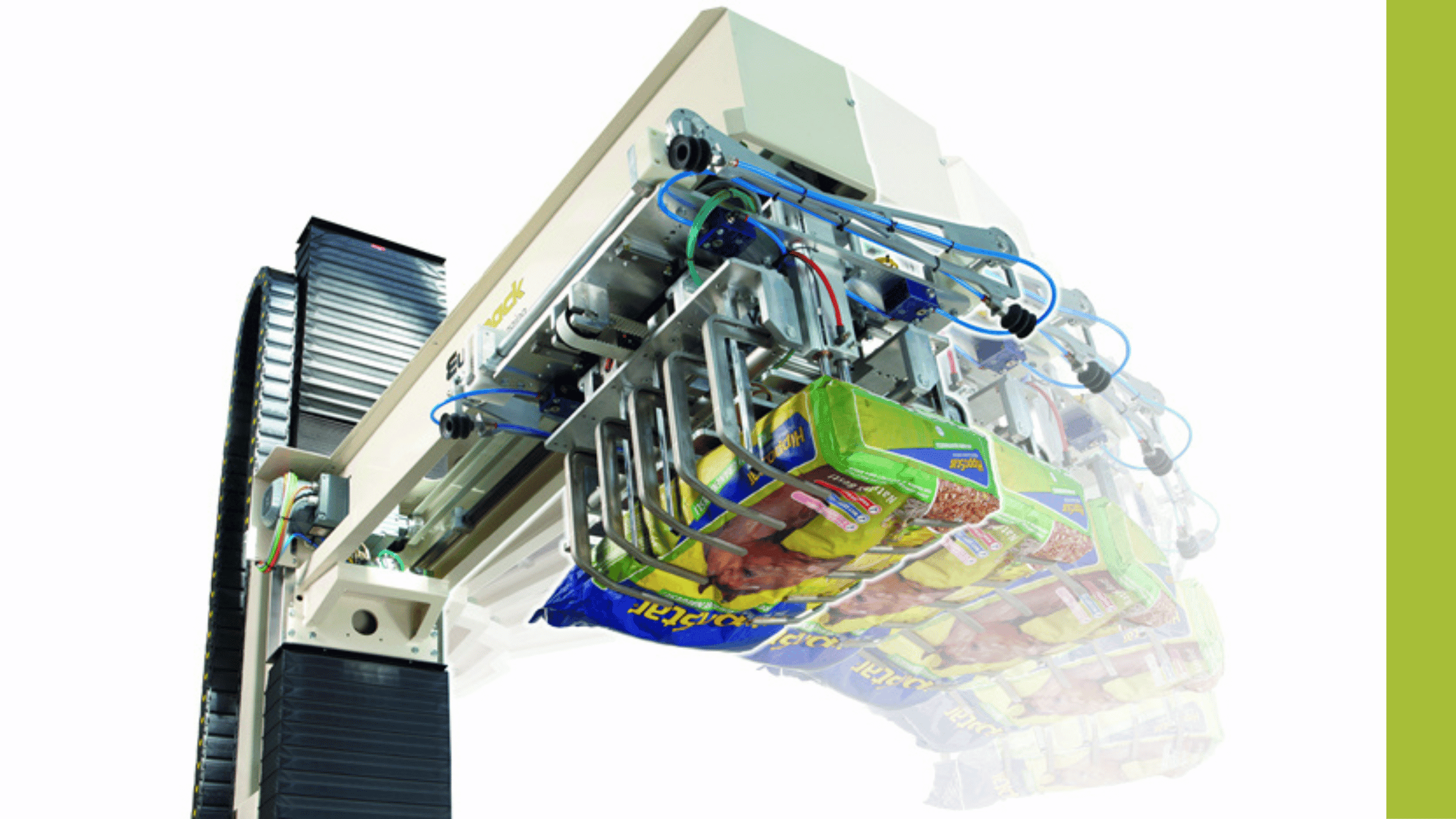

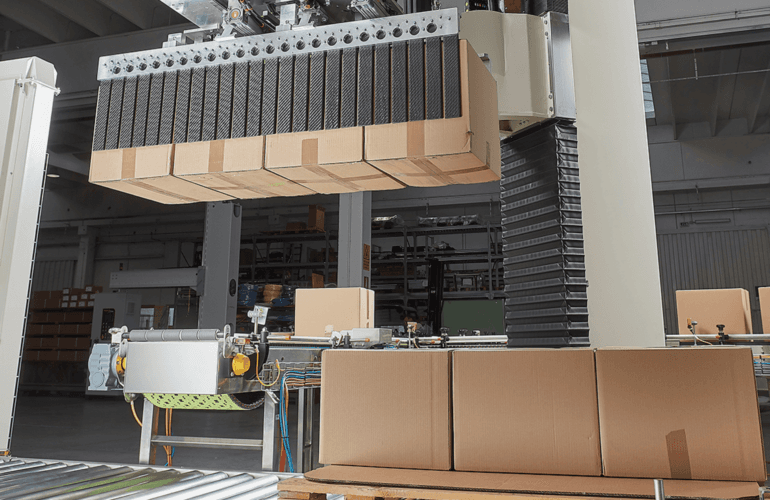

Rotating beam palletisers maximise space on the factory floor. They function around one beam with a fixed arm and a product picking head that can rotate 360° on its axis. This gives the unit a small footprint but good reach.

Heavy loads

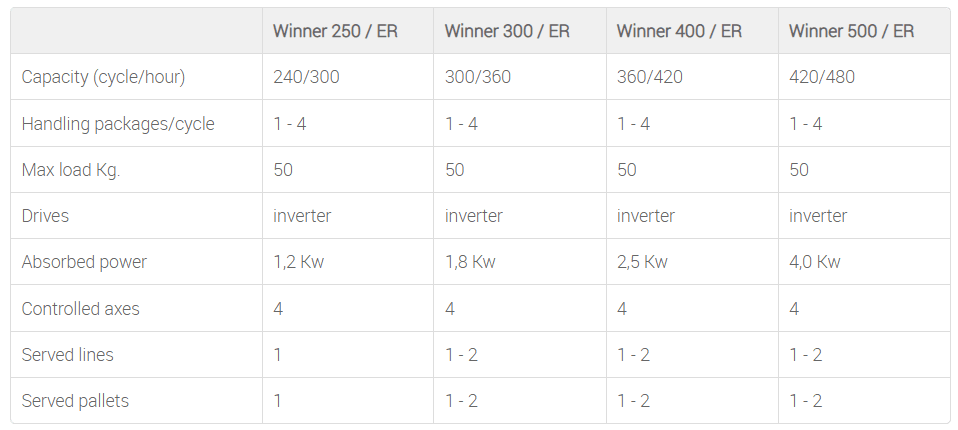

The rotating beam palletisers PALpack offer are supplied from top European manufacturer Europack, who invented this kind of machine. Their Winner range can lift up to 50kg and handle up to four packages per cycle.

Speed and flexibility

Despite the smaller footprint, rotating beam palletisers maintain the flexibility and speed of a 4-axis unit, with up to 800 cycles per hour.

Energy reduction

Europack have developed a control and recovery of energy costs system called KERS (Kinetic Energy Recovery System). Instead of losing the kinetic energy produced by braking through heat, KERS instead generates electric power, which goes towards the power supply of the unit’s electrical devices. This significantly reduces running costs.

Integration

At PALpack, we can set up a rotating beam palletiser to work with any existing automation. We can also use the same machine to collect pallets or layer cards, and even have multiple lines feeding into the same machine.

Europack technical features

Ready to get ahead of the competition?

PALpack has been working with automated machinery for over 25 years. We use our engineering experience in design, production and workflow to ensure any automation we implement is the best solution to meet your business goals. Get in touch with PALpack to discuss how a rotating beam palletiser can benefit your business.