The needs of modern manufacturers are evolving: more competition, higher customer expectations and rising costs mean they’re under increasing pressure to improve throughput and enhance efficiency.

For many, this means automating processes – and companies such as Europack are leading the way with advanced technology and innovation. In this blog, we’ll explore Europack’s cutting-edge solutions and how they’re helping companies not only streamline their production lines but also improve sustainability.

Who is Europack?

Europack is a leading name in automation, known for designing and building palletisers and packing equipment to automate end-of-line processes. Started in Italy in 1998, the company now operates in 50 countries and across a wide range of sectors, including food, pharmaceuticals and consumer goods.

Renowned for its research and development and commitment to quality, Europack has established itself as an industry leader by consistently delivering innovative solutions that are both robust and reliable.

Europack’s innovative solutions

Europack’s experts are responsible for two stand-out developments within the industry.

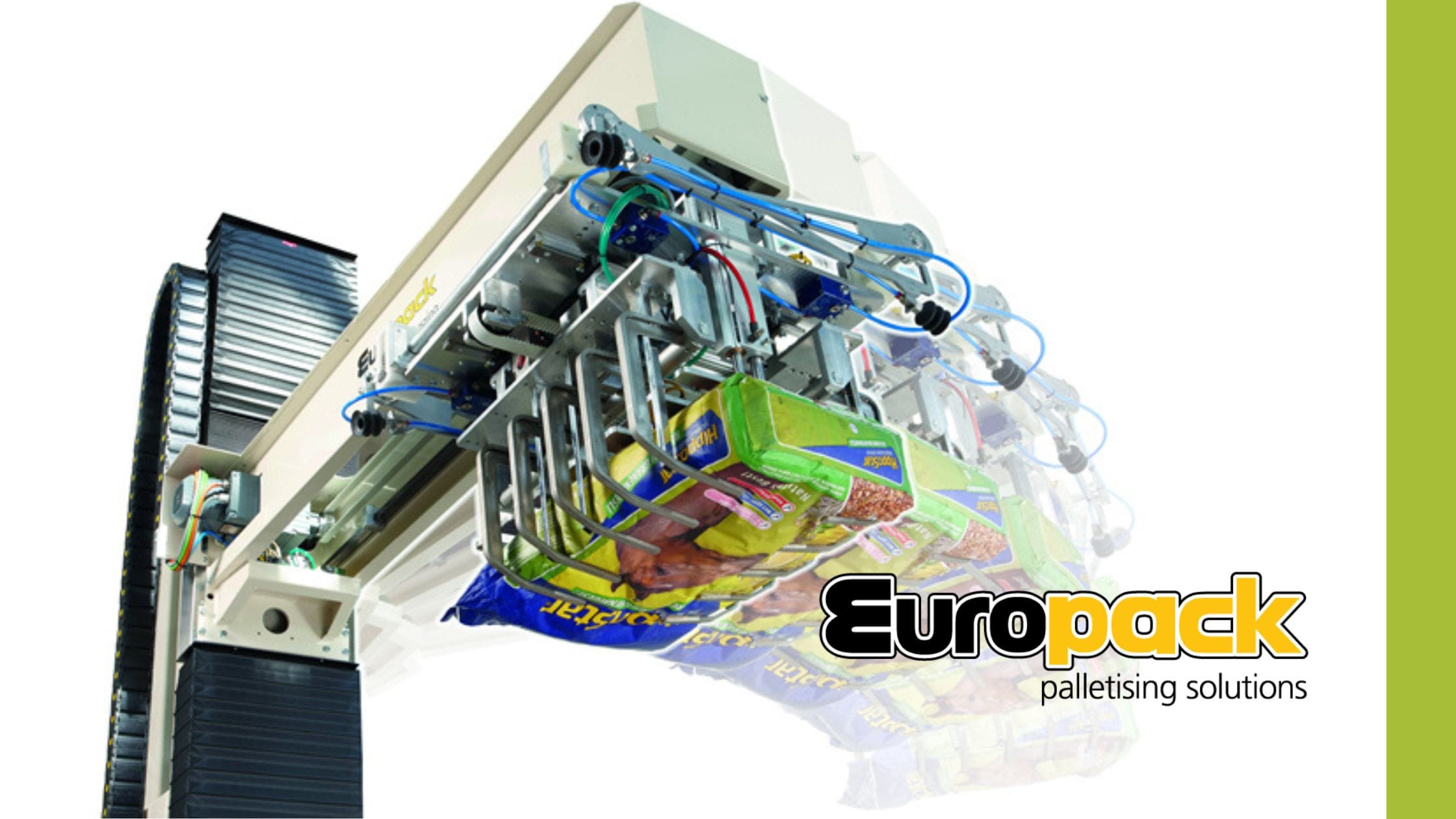

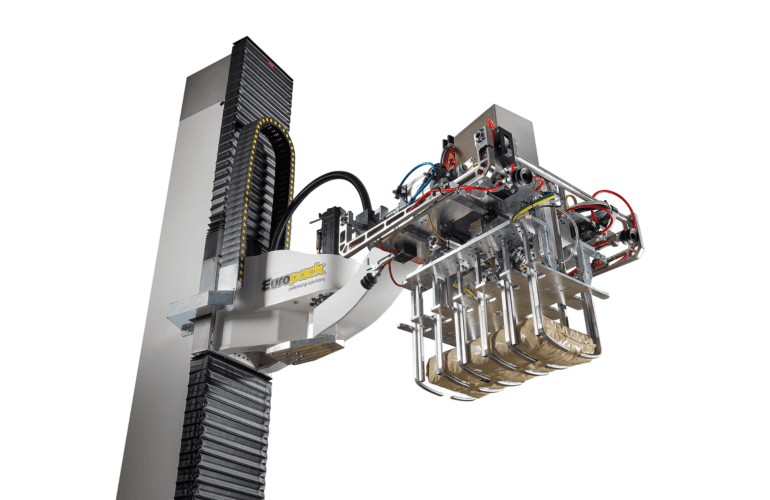

- The world’s first rotating beam palletiser, a robot palletiser that picks up and stacks goods on a pallet using a pre-determined pattern of movements. The design has been frequently replicated, but no one has managed to achieve exactly the same thing. Featuring one beam with a fixed arm and a product picking head, it has a small footprint but good reach to maximise space on the factory floor.

- The Winner Green range of palletisers includes the clever Kinetic Energy Recovery System (KERS), cutting-edge technology that captures and reuses energy that would otherwise be wasted during the deceleration or stopping process. Similar to the technology used in hybrid cars, harnessing this reclaimed energy reduces energy consumption by up to 70%.

Tailored systems meet diverse needs

Europack’s automated palletising systems can be customised to handle a wide variety of products from cans and bottles to boxes, bags and bundles. Robot palletisers are equipped with a 360° rotating gripper head that can be changed to suit different products, or fitted with combined heads that can deal with more than one type of package.

Additional features include accessories such as empty pallet store dispensers, interlayer handling devices and automatic pallet picking-up devices, all of which are designed to minimise manual intervention, creating a safer working environment while increasing operational efficiency.

The flexibility of the systems also means they can be integrated with any existing automation. The small footprint makes them suitable for diverse plant layouts and, with the ability to feed multiple lines into the same machine, they’re highly efficient too.

A future-focused approach

Europack’s combination of innovative thinking and sustainability makes it the perfect partner for manufacturers looking to remain competitive in the industry. By embracing automation and green technology, manufacturers can not only boost their efficiency but also meet environmental regulations and reduce their carbon footprint – a key differentiator in today’s market.

To find out how Europack can transform your production line, contact us for more information.