As the global race towards net zero intensifies, manufacturers have a growing part to play in reducing carbon footprints and improving sustainability across every stage of production.

In 2022, the sector was responsible for 14% of UK greenhouse gas emissions, and while this figure has decreased significantly since 1990, there is still a way to go to meet the government’s target of net zero manufacturing by 2050.

The shift is being driven by consumers too. Today’s buyers are increasingly eco-conscious and expect the brands they support to reflect those values. Manufacturers who supply directly to end consumers can strengthen their reputation, build trust and increase market competitiveness by demonstrating their commitment to sustainable automation.

How automation supports sustainability

End-of-line operations – from sack filling to palletising – are ideal areas to target when it comes to improving eco-credentials. By introducing automation, manufacturers can improve precision, reduce waste and optimise energy usage, all while boosting efficiency.

1. Reducing waste through precision

Automated machinery delivers accuracy and consistency far beyond what is possible manually. In tasks such as sack filling, precision is key: automated systems ensure each bag is filled to the exact required amount, preventing overfill and eliminating product waste. Automated systems also help prevent human error, ensuring that goods and materials are handled correctly every time. This significantly reduces the amount of product and packaging that ends up damaged or unusable and has to be discarded.

2. More productive operations

Automation accelerates production, enabling more to be achieved in less time. Whether your line runs 9 to 5 or 24/7, automated systems perform tasks faster and more efficiently, reducing the need for prolonged lighting, heating and equipment use. The result is lower operational energy consumption with increased throughput, improving both sustainability and productivity.

3. Reduced energy consumption

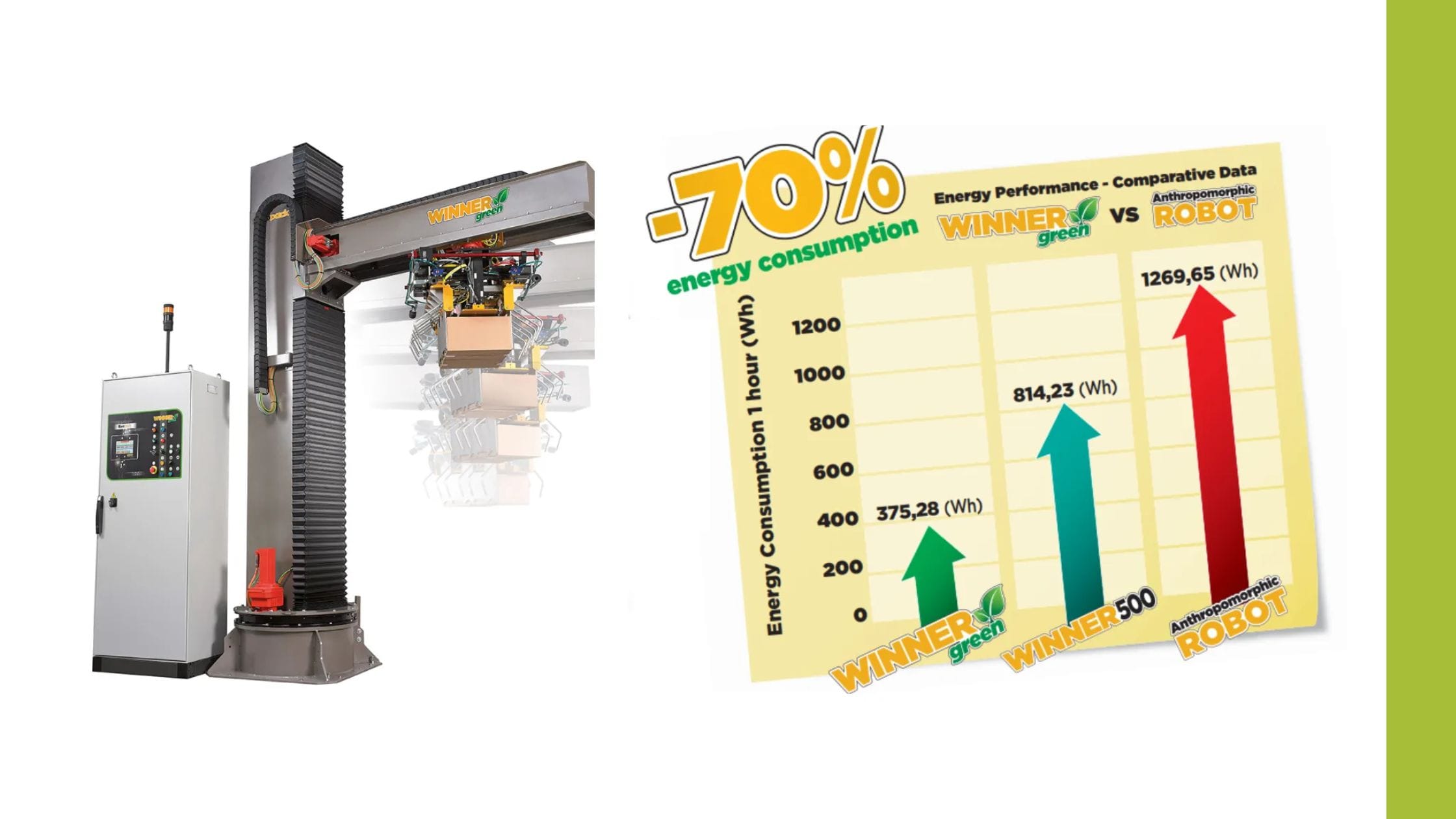

Choosing the right technology can significantly reduce your carbon footprint. For example, Europack’s Winner Green range of palletisers features innovative KERS (Kinetic Energy Recovery System) technology, which transforms wasted energy into usable power. Much like the regenerative braking technology in hybrid vehicles, KERS captures and reuses energy generated during machine deceleration, reducing overall energy consumption by up to 70%.

4. Sustainable packaging

Other technology providers minimise waste and environmental impact in other ways. Gampack’s Green Line includes solutions like the Mini Tray, Eco Label, and I-Layer, which offer alternatives to plastic-heavy packaging and reduce material usage. Machines also feature energy-efficient motors and systems to reduce energy consumption and space-saving layouts for small spaces.

5. Predictive maintenance for long-term efficiency

Automated systems increasingly feature predictive maintenance tools that monitor equipment condition in real-time. By detecting potential faults before they cause breakdowns, manufacturers can avoid energy waste from inefficient operation, reduce the need for emergency repairs and extend machinery lifespan — all of which support both operational efficiency and sustainability.

Build a greener end-of-line process with PALpack

From reducing waste to cutting energy use, sustainable automation offers manufacturers a practical, cost-effective route to environmental improvement. Whether you’re interested in energy-efficient palletisers or innovative packaging machinery, we can help.

To find out how PALpack’s solutions can support your sustainability goals, get in touch.