Manufacturing is an industry well-known for reaping the rewards of automation, and if you’re thinking about joining them in this, then you’re probably wondering where to start. In this blog, we look at how to automate manufacturing processes, and where to find the right support.

Automating manufacturing processes step-by-step

The journey to automation begins with a series of preparatory steps, and we’ve covered them here so you know exactly what to expect.

1. Review your current processes

Before you can introduce automation into your business, you should review your current processes. If you have a process map which lays out the manufacturing tasks your business undertakes, use this as a starting point.

This will help you identify the inefficiencies in your production processes – in other words, the sticking points in your current system that would benefit from being automated.

2. Identify what can be automated

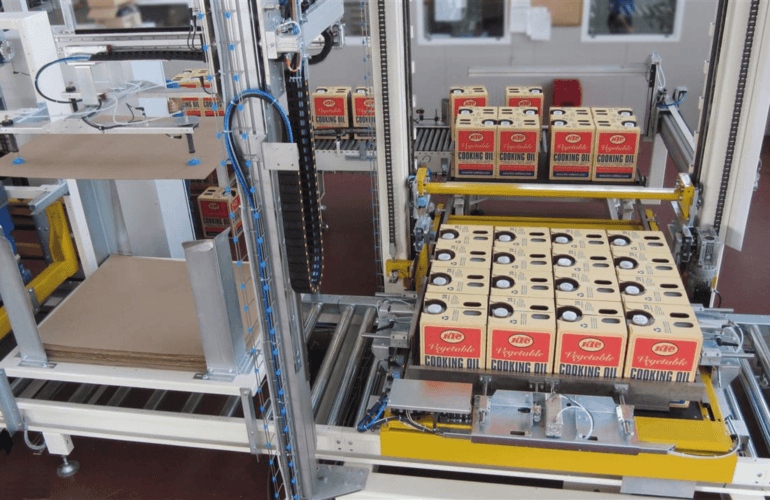

Some production processes lend themselves to automation better than others. Once you’ve identified the most inefficient areas, narrow down what can be automated. For example, repetitive, labour-intensive tasks are ideal for replacing with robotic solutions.

3. Define what you need it to do

Before you approach a supplier, it’s useful to have a rough idea of what you need your automation equipment to be able to do. You’re more likely to get an accurate quote if you already know what you want the machinery to achieve.

4. Find an automation supplier

The best way of finding a supplier is to ask for recommendations from other people in your industry. If this isn’t an option, then most reputable companies will have reviews, testimonials, and case studies on their website.

When you’re meeting with potential suppliers, look for assurance that your business goals align and that you’re both striving for the same outcome.

What is a user requirement specification?

A user requirement specification (URS) is a planning document that sets out what you want from your automation equipment. It should include what you are replacing and what problem it will solve.

Like any brief, it ensures that everyone starts with the same understanding and prevents any confusion or ambiguity. You have a much better chance of being successful if you are clear from the outset what you want to achieve.

Read more on this in our blog on how to write a user requirements specification for manufacturing automation.

Where to find help for your business

There are two ways you can access support for your business:

- you can approach a manufacturer directly or

- use a manufacturing automation consultant

With a consultant you’re guaranteed an unbiased view, because they have no financial interest in selling you one brand of machine over another. They also have years of accumulated knowledge and a wealth of experience across different markets.

When it comes to understanding how to automate manufacturing processes, we have over 20 years’ experience at PALpack. We’re experts in finding the best possible solutions for our clients, and we’ll be with you from beginning to end.