Spider Robots has been building automatic packing and palletising lines for over 30 years, and are one of Europe’s leading suppliers of palletisers. PALpack is proud to announce that we are the UK’s official agent for Spider Robots.

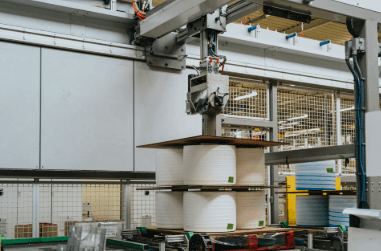

Spider’s modular palletiser has many impressive features which makes these machines easy to use, very flexible, and compact.

Easy programming

Adding new programs to a Spider palletiser could not be easier as everything is animated on the screen. Simply add your pack size, add your pallet size and the Human Machine Interface (HMI) displays an animated representation of the pack and pallet.

From the HMI, you can move the pack into the position on the pallet, rotate and nudge until it’s in its ideal place. Add another pack and continue until you’ve finished the layer. It’s that easy. You can have up to four variations of layer pattern. Once you have designed your new pallet pattern, simply save it, and recall it whenever you need to in the future.

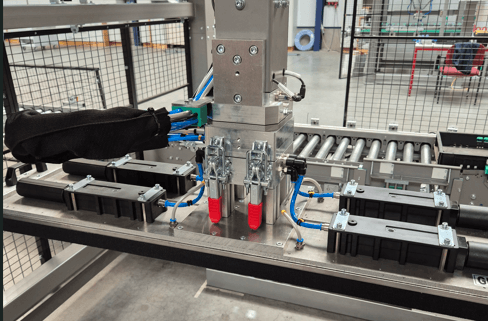

Quick changeovers

If you need multiple grippers for different pack types, then Spider’s clever quick changeover system makes it simple to do. Each gripper is supplied with an interchangeable connection block. Simply release the four clamps, remove the gripper, place the new gripper into the mating block and snap the four clamps on. All electrical and pneumatic connections are inside the end of the vertical axis, so no need to make any connections. Changeovers are as quick as a couple of minutes.

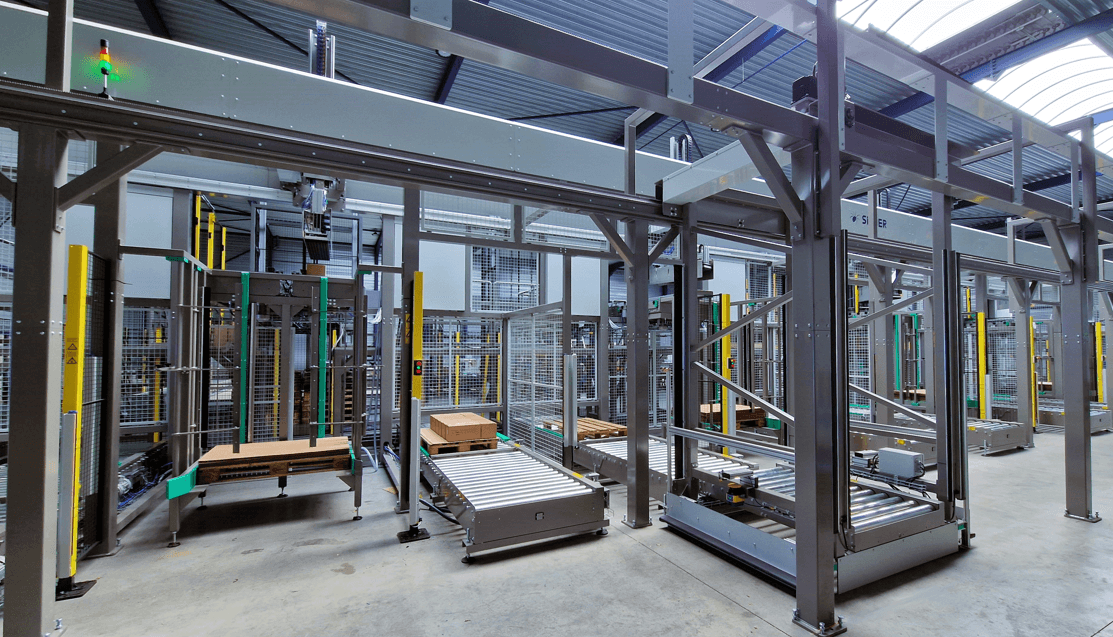

Modular design for single or multiple production lines

Spider’s system has been designed so that you can have a single production line palletiser, or if you have multiple lines, the frame is extended to accommodate as many lines as you need. If one pick and place head can manage multiple lines, then one head is used – if more are needed for faster production, then more robot gantries can be added.

Flexibility

These palletisers can be fully automated, by adding further modules, such as:

- Pallet de-stackers

- Layer card magazines (including plastic sheets, trays and ridged plastic sheets)

- Pallet conveyors

- Pallet wrappers

- Empty pallet re-stackers

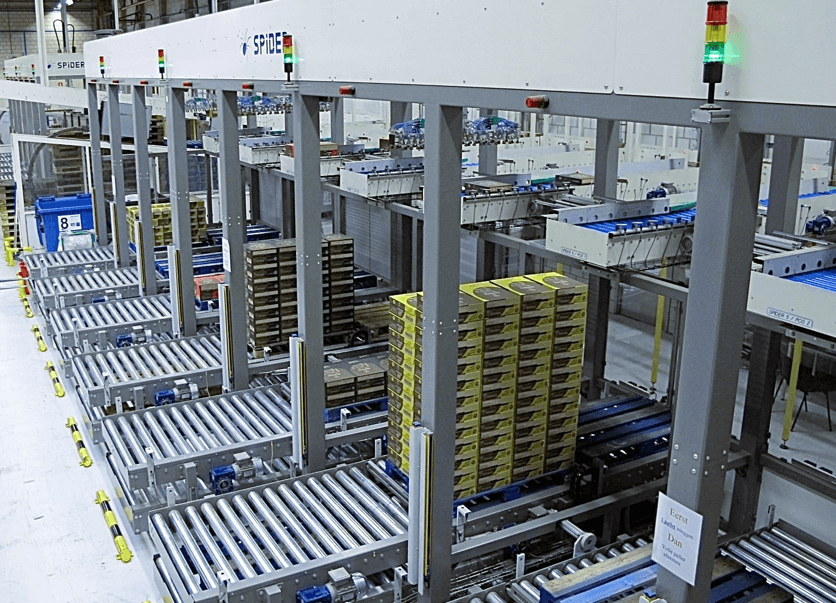

Speeds

These machines can move at a rate of up to 10 cycles per minute. Each cycle can pick multiple packs up, and one of the great innovations from Spider is that, even when multiple packs are lifted, the robot can place each pack into a separate location on the pallet. If the gripper picks four packs up, the robot can move over the pallet into four different positions and place one pack into each. This makes 10 cycles into many more packs per minute. The Spider system also accommodates full layer palletising and de-palletising.

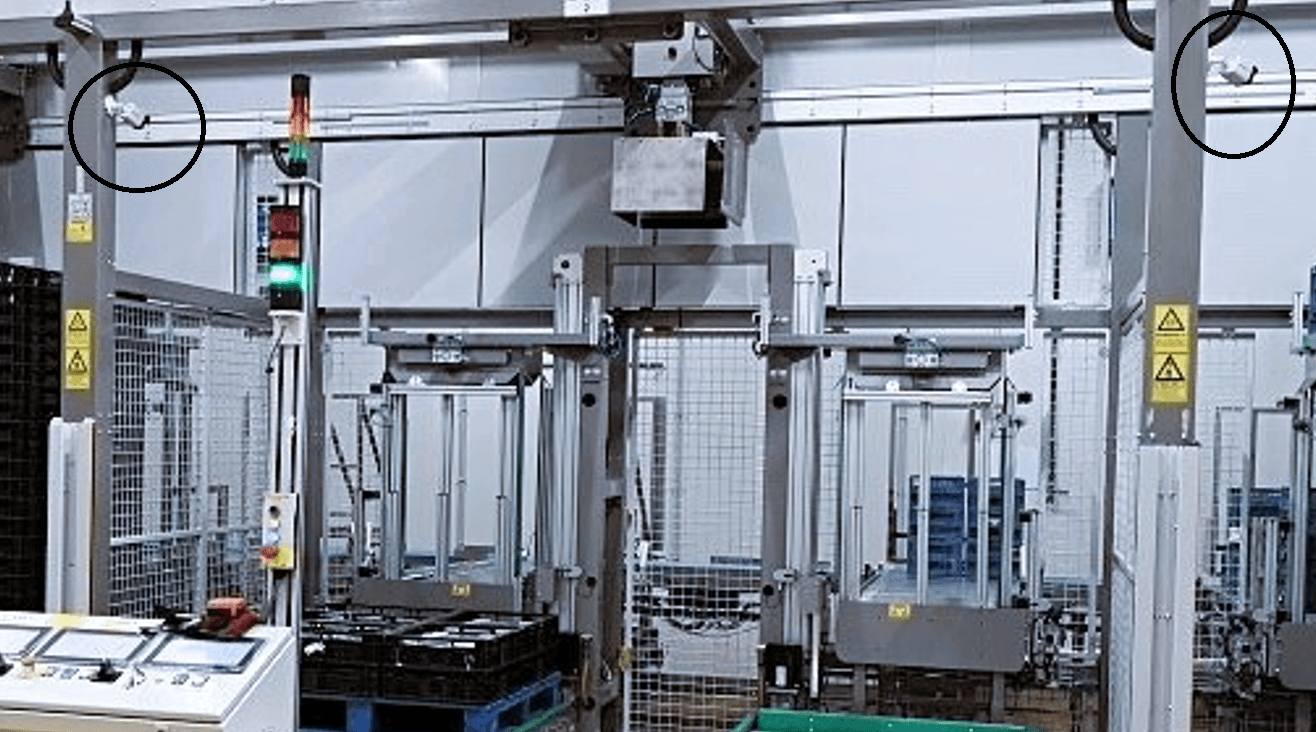

Backup and support

Each machine supplied by Spider has remote access VPN connections. But it doesn’t end there. Each machine is supplied with several cameras which allows access to video from the previous few months, where we can find and identify any issue with the machine or how it has been operated. This is a standard part of Spider Robots offer and makes our backup and support unrivalled. If we need to come to site, we will already know what is needed and can make sure that any spare parts are with our engineers.

Interchangeable parts

Spider has designed their machinery in such a way that all motors are the same size, as well as all sensors, inverters and all other major components. Because of this, you only need a very small spares kit. Our engineers also have a full set of spares in their vehicles, so, when a service or repair is carried out, we can fix anything in one visit.

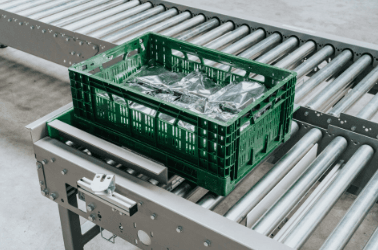

Products handled

- Boxes

- Trays

- Crates

- Buckets

- Jerry cans

- Drums

- Foil wrapped goods

- Bags

- Sacks

- Doors

- Breakbulk items

- Rolls

- Large panels

- Individual picks to complete layers

To find out more about how we can augment your manufacturing operation with Spider Robots, just get in touch to book your free consultation with PALpack.