Palletising robots are helping warehouses reduce labour costs, improve accuracy, and increase throughput. This blog post explores the key benefits of automation and highlights how Spider Robots, available through PALpack, deliver a fully integrated palletising solution.

From manual handling to robotic palletising

As warehouse operations grow more complex, businesses are looking for ways to reduce labour costs and increase efficiency without compromising reliability. Palletising robots are proving to be one of the most effective ways to achieve both.

Manual palletising is repetitive, time-consuming, and often requires a large team to keep up with demand. By contrast, a palletising robot can manage high volumes around the clock with minimal supervision. In many cases, systems such as the Spider Robot require only two operators to achieve what previously needed a team of ten or more. This frees up staff to focus on higher-value tasks.

How palletising robots improve performance

Palletising robots deliver consistency that’s difficult to achieve manually. Each movement is precise, ensuring cartons or bags are stacked accurately according to the chosen pattern. The result is stable, uniform pallets that make handling and transport safer and more efficient.

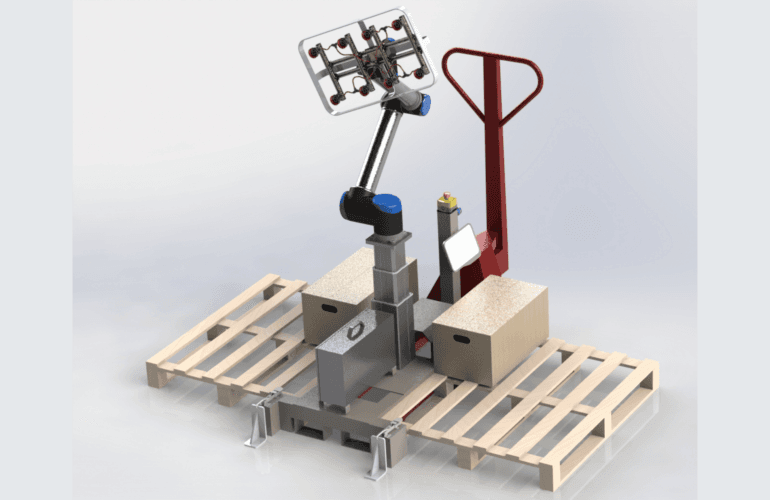

Through integrated vision systems, Spider robots can automatically identify, sort, and position products. This technology allows the system to rotate and align rows before stacking, ensuring the correct orientation every time. The entire process, from infeed conveyors to full pallet outfeed, runs automatically, with options for turntables, top sheet placement, and wrapping.

Flexible palletising for different products and setups

Spider palletising robots offer practical features that make a noticeable difference in day-to-day warehouse operations. A quick-release device allows the gripper head to be switched in minutes, enabling smooth changeovers between different product types, such as cases and bags.

Spider’s built-in camera system records and stores three months of video data, helping teams diagnose and resolve any issues remotely. Engineers can review footage before visiting site, which saves time and keeps downtime to a minimum.

A complete robot palletising solution

Supplied exclusively in the UK by PALpack, Spider Robots provide a fully integrated palletising system designed for warehouses and distribution centres aiming to increase throughput, accuracy, and operational safety. With a capacity of up to 800 cases per hour, it combines speed, reliability, and intelligent automation in one solution.

Learn more about Spider Robots and how they can improve your warehouse performance: