More businesses than ever are using collaborative bots to help boost their productivity, but there is a natural apprehension that surrounds autonomous mobile robots (AMRs), as there is with any kind of machinery that works alongside people in a shared space.

So, just how safe are they, and do we need to be concerned? In this blog, we look at how AMR safety is evolving to keep pace with the rapid uptake of autonomous machinery.

Autonomous mobile robots – what are the concerns?

AMRs are designed to perform tasks in close proximity to other people and machinery. To do this safely, they need to be able to recognise quickly when there is an obstruction and navigate around the problem.

If the robot was to collide with something in its path, it could cause significant damage, or in the case of a co-worker, a severe injury.

Manufacturers have recognised this concern, and to manage the risk of collision, they’ve added safety mechanisms to their AMRs. What this means in practice is that at the point you unbox your machine, it’s already set up to protect your workforce.

What manufacturers are doing about AMR safety

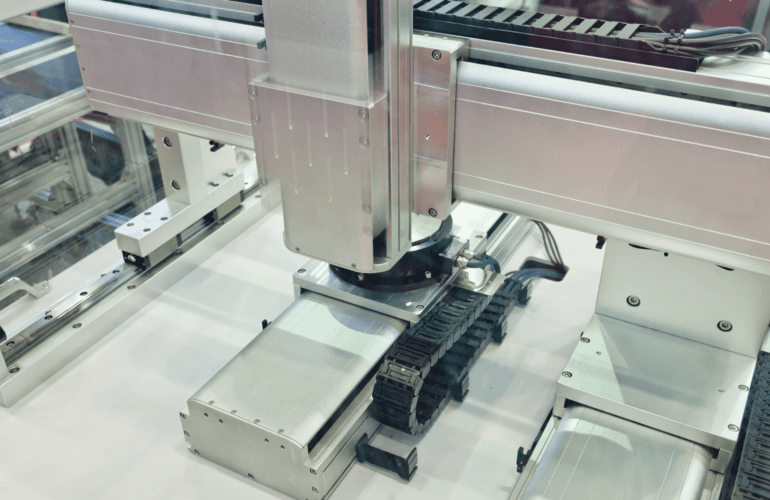

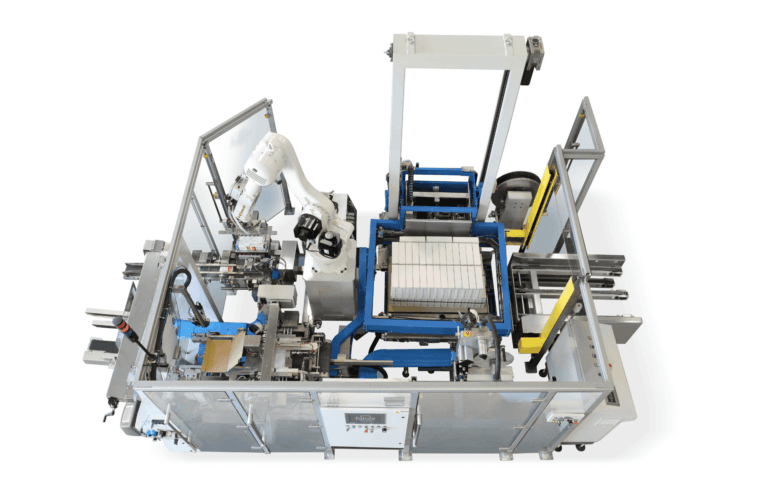

The AMR’s in-built safety features are there to help it detect obstacles in its path, and then decide what action to take next – slow down, stop, or change direction.

It does this using sensors and scanners that give it a 360° field of view so it can monitor what’s happening around it.

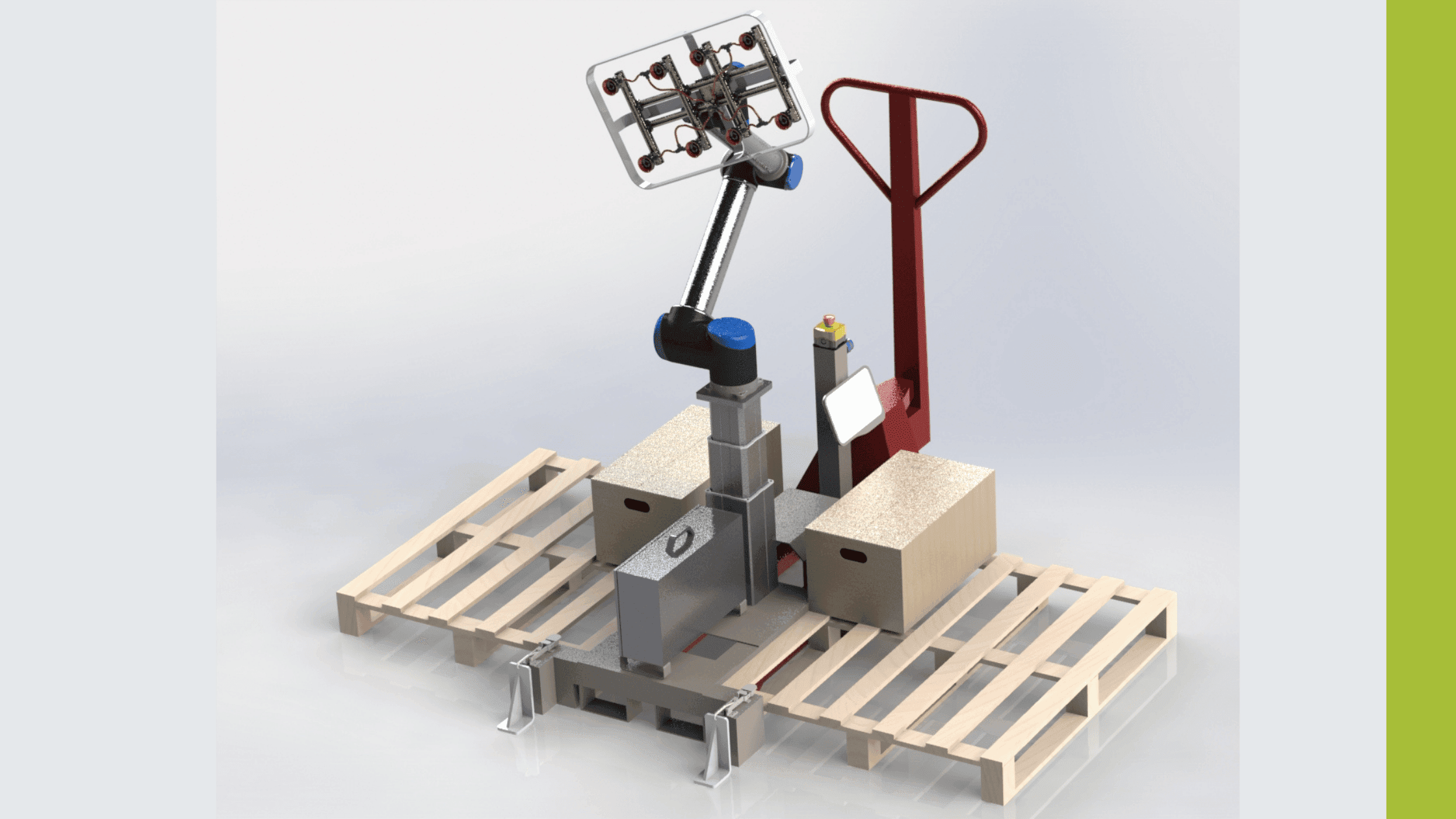

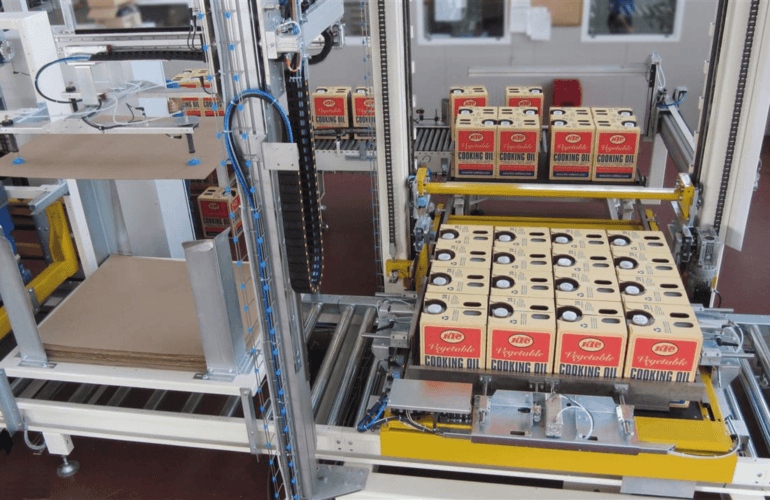

As an example, a robotic palletiser might include things like:

- a laser scanner

- a safety light curtain and guard switches

- an emergency stop button

The laser scanner is there to detect obstacles – like people – that have entered its working area, and then send instructions to stop the machine.

Watch the Clevertech robot palletiser in action to get a feel for how it works.

AMR safety – the end user’s responsibilities

The safe use of an autonomous mobile robot is not just down to the manufacturer – the end user also has an important part to play in handling it.

This starts with a risk assessment to identify and eliminate potential hazards in the workspace. Creating the right conditions for the AMR to work in will have a significant impact on its safe operation.

Most AMRs can be programmed to follow a predetermined path that you can ensure is free of any obstructions. It can also be set to avoid certain areas (forbidden zones) or to give out a warning signal when it enters a high-traffic area.

This relies on the machinery being set up correctly to begin with, and for this, an end-user may need the help of an experienced integrator or consultant.

What does the future look like for AMR safety?

Technology is evolving all the time, and so too must the regulations that govern it.

Perhaps one of the most important is ISO 3691-4: 2020, which outlines the safety requirements for autonomous mobile robots and other driverless trucks.

Inevitably, these standards will change as technology moves on, and it’s our responsibility as consultants, integrators, and end-users to keep pace with this change.