As you would think, pick and place robots pick up items, and place them somewhere else. They can do this with an incredible degree of accuracy, and much faster than humans carrying out the same task. They are ideal for manufacturing environments and can really help boost production rates. What are they used for, and what are the benefits of using this kind of automation?

The three main uses of this kind of automation are for assembly, packaging and inspection.

- Assembly

Pick and place robots can play an important part in the manufacturing process in all kinds of industries. They lift a part from one area, such as a conveyor, transport it somewhere else and either place it down in an assigned location, or attach it to another part.

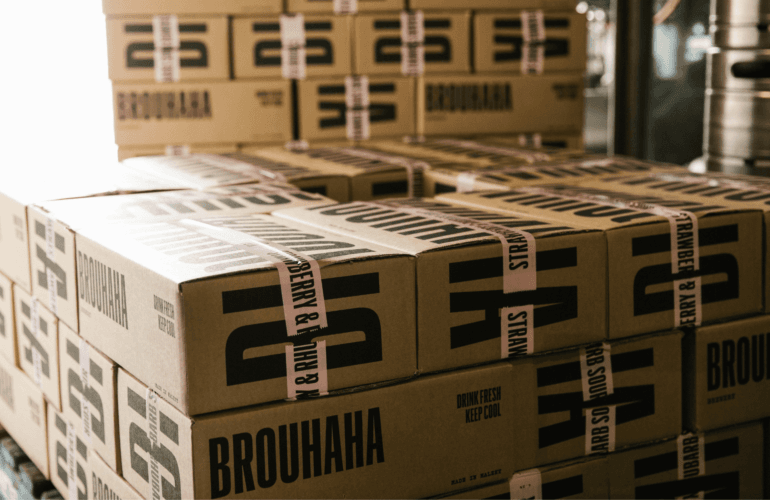

- Packaging

Grabbing items that are ready to be packaged, a pick and place robot can place them into a container. Also called Cartesian palletisers, they can even work on multiple lines to maximise their capacity.

- Inspection

With the help of an advanced vision system, robots can identify faulty items on a production line and remove them to a designated location.

Types of pick and place robots

Pick and place robots can come in various forms – robotic arms, Cartesian, Delta and cobots.

- Robotic arm

These are probably what you imagine when we talk about pick and place robots as they’re the most common. They usually function on five or six axes, depending on whether an item needs turning for placement or examination.

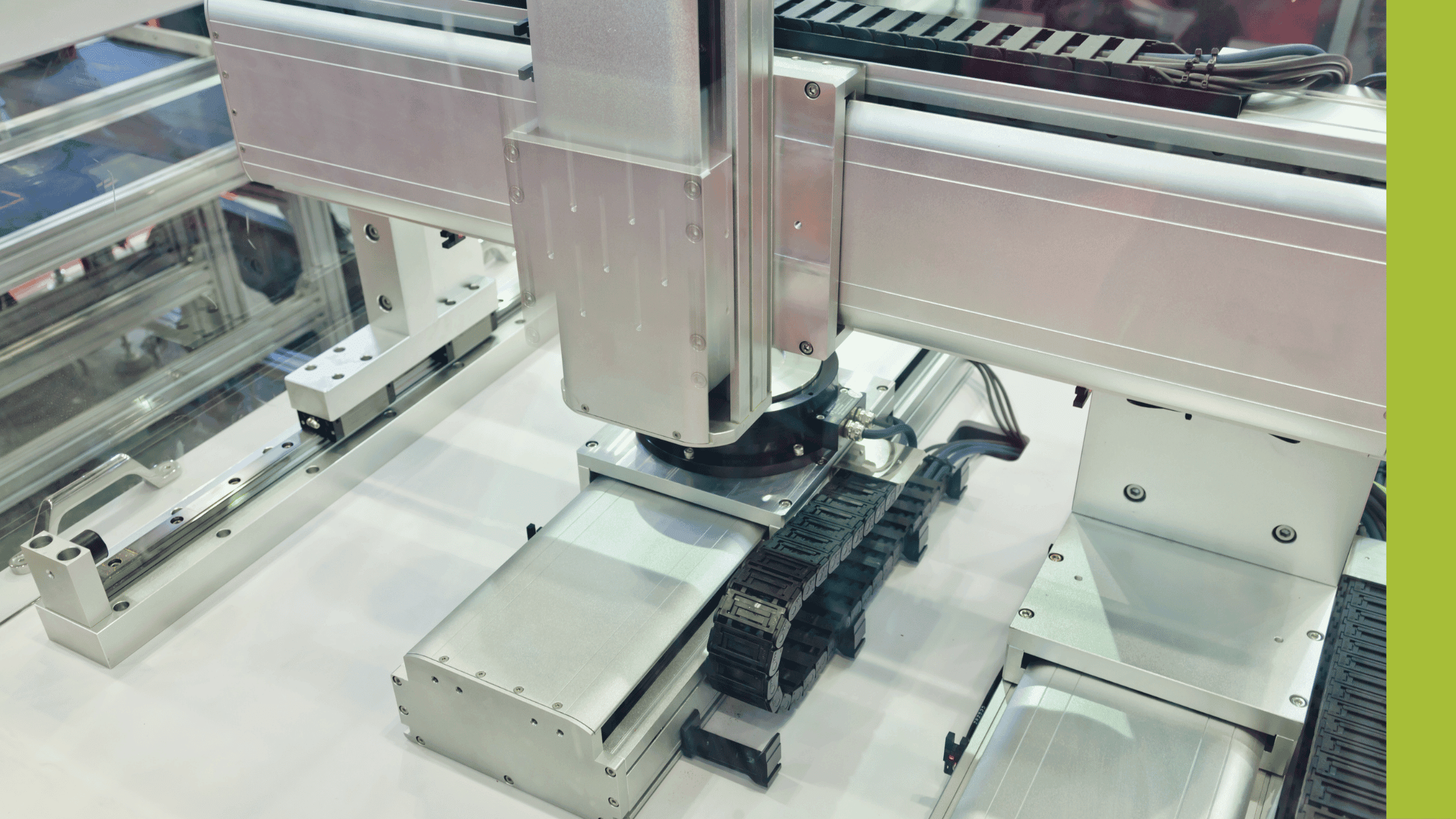

- Cartesian

Cartesian coordinates allow you to position a point in three dimensional space. As such, Cartesian robots are gantry pick and place robots which function from structural beams and work on three axes (X, Y and Z) to position items. They tend to have better positional accuracy compared to the robotic arms above.

- Delta

A Delta is a ceiling-mounted parallel robot, which operates on three axes like the Cartesian models. It performs low-skill tasks, but can move very quickly, making them very popular for picking and packing.

- SCARA

SCARA stands for Selective Compliance Assembly Robot Arm, or Selective Compliance Articulated Robot Arm. SCARA robots move similar to a human arm, with shoulder and elbow joints which rotate around a vertical axis.

Benefits of pick and place robots

There are many benefits to employing a pick and place robot in a manufacturing setting. They include speeding up processes, relieving the human workforce of repetitive tasks, and maintaining accuracy. They’re configurable to your needs and can serve more than one line at a time. The boost in productivity ensures that the businesses not only see a fast return on investment, but that they remain competitive in their market.

Constraints

The main constraint on pick and place robots is choosing a unit that doesn’t serve the future needs of the manufacturer. This is why it’s important to fully understand and document your requirements for a machine before purchasing.

Want to chat?

If you’re considering pick and place robots for your business, please get in touch for free automation advice.