Pick and place machines automate the loading and unloading of products during the packaging and palletising process. They are designed to handle repetitive movements quickly and accurately, improving efficiency while reducing the risk of product damage.

In this guide, we look at the key factors to consider before investing in a new pick and place machine and highlight the solutions available through PALpack, including advanced systems from Spider Robots.

What to consider when choosing a pick and place machine

There are several machine types available, from simple cartesian systems to high-speed robotic models. The best option will depend on your throughput needs, the type of products handled, and how well the equipment integrates with existing machinery.

When choosing a pick and place machine, it’s important to assess both current and future production goals. The following factors should be carefully reviewed:

- Speed and throughput: Determine the number of cycles per minute required to meet production demand without creating bottlenecks.

- Payload and product type: Machines must handle the weight, size and shape of your products safely and consistently.

- Flexibility: If your product range changes frequently, consider equipment that allows for quick gripper or tool changes.

- Integration: The system should work seamlessly with conveyors, wrapping machines, and palletisers.

- Footprint and layout: Evaluate how the machine fits within your existing floor space and production flow.

- Support and maintenance: Access to reliable technical support and spare parts is essential for long-term performance.

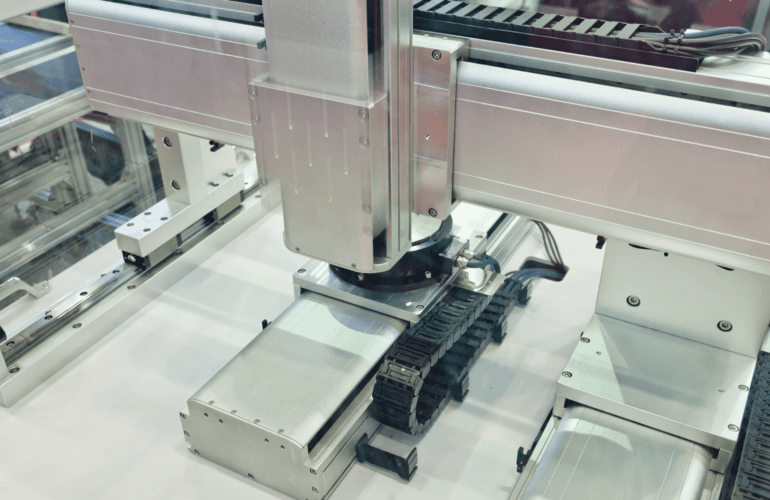

Cartesian pick and place machines

Cartesian or “pick and place” palletisers use a series of linear axes to move products along three directions (X, Y and Z). Their simple, robust design makes them ideal for operations that require precise placement or specific pallet patterns.

Although they typically run at lower speeds than robotic systems, cartesian palletisers offer excellent flexibility. Products are collected from an infeed conveyor using a gripper head and placed accurately on the pallet. Some models can work across multiple lines simultaneously or use interchangeable heads to pick several products at once.

PALpack’s cartesian palletiser range can be configured to suit different layouts and capacity requirements. Options include single or multiple pick heads, and integrated interlayer or pallet-picking devices, providing an adaptable solution for varied production needs.

High-speed robotic pick and place machines from Spider Robots

For higher throughput and greater flexibility, PALpack supplies advanced robotic systems from Spider Robots, one of Europe’s leading manufacturers of palletising and depalletising solutions. Spider Robots’ pick and place machines combine precision handling with intelligent motion control to deliver consistent, reliable performance across a wide range of product types.

As the UK agent for Spider Robots, PALpack provides complete support from consultation and system design through to installation and aftercare. This partnership ensures every system is tailored to meet each customer’s unique production and layout requirements.

Understanding speed, weight and cycles per minute

When assessing the performance of a pick and place machine, speed figures can sometimes be misleading. The quoted movement speed of a robot or palletiser doesn’t always reflect real-world conditions, because product weight has a major influence on how fast a machine can safely operate.

When a heavy item is moved quickly, inertia becomes a key factor. The challenge is not only accelerating the product but stopping it in a controlled way. If a machine stops too abruptly while carrying a heavy load, the servo drive may trip, causing downtime. This means that heavier products must be handled at a controlled speed, which can reduce the overall cycle rate.

For this reason, pick and place systems can sometimes be the better option for handling heavier products. Cartesian palletisers, for example, are often more robust because the size of the drives and motors can be specified according to load requirements. In contrast, robotic arms are generally supplied with fixed drive sizes that are not easily changed.

Another important performance measure is cycles per minute, meaning the number of times the machine can move from the pick-up point to the place point and back again. However, the true measure of productivity is not just how many cycles can be achieved, but how much product is handled per cycle.

For example, if a system performs eight cycles per minute and each cycle lifts six cases, it is effectively palletising at a rate of 48 cases per minute. Understanding both the speed and payload capacity helps ensure a realistic comparison between systems and avoids being misled by headline speed claims.

Making the right investment

Choosing the right pick and place machine is an important decision that affects productivity, efficiency and long-term costs. Taking time to evaluate your needs, understand system capabilities and work with an experienced automation partner will help ensure a successful investment.

Whether you need a flexible cartesian palletiser or a high-speed robotic solution, our team can help you find the best fit for your operation. Contact us to talk through your requirements with a member of our team.