A pick and place machine is typically used in a manufacturing or industrial environment to pick individual items from one location and place them in another. The automated equipment is accurate and fast and can even place items in a predefined pattern, making processes such as palletising (the stacking of goods onto pallets for transportation or storage) much more efficient.

The features of a pick and place machine

Pick and place machines can be programmed to handle a variety of different products effectively, but there are a number of core features that help to consistently deliver benefits.

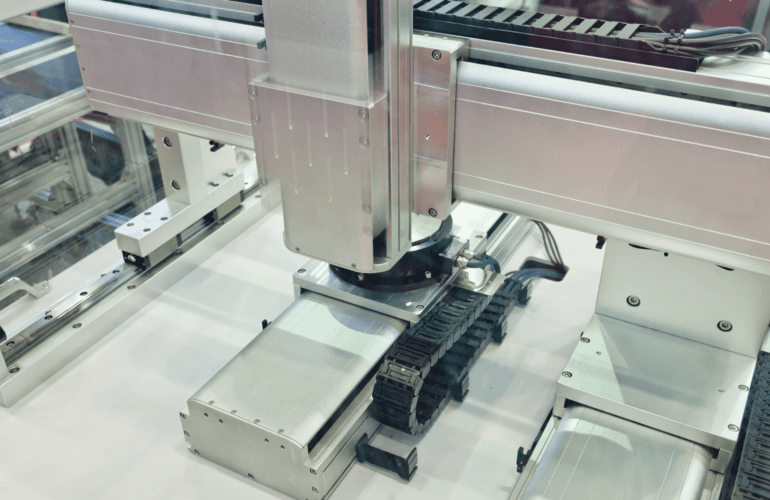

- Pick and place mechanism – the core of the system is the pick and place mechanism, which is often a robotic arm, or a cartesian system with a specialised gripping head that can lift and move packages securely, without any damage.

- Handling systems – configurations can vary but this may include conveyor systems to transport items to be palletised to the pick and place area in a controlled manner and pallet handling systems to position and move pallets into the correct location for loading.

- Vision system – Many modern pick and place palletisers incorporate vision systems or sensors to identify the location, orientation, and type of items being handled. This allows the system to adapt to different product variations and ensures accurate placement.

The functions of a pick and place machine

As we’ve already mentioned, pick and place robots can be configured to work with many different products or palletising patterns and this makes them useful for a range of tasks, especially in industries such as electronics, automotive, and consumer goods.

Some of the most common jobs to be carried out by the machines include:

Assembly

Pick and place machines can ensure precise placement of components and fast, accurate assembly. Parts are picked from a conveyor and put together according to design specifications to create electronics and a wide variety of other products.

Packaging

Pick and place palletisers can pack items onto pallets at a very high speed. Unlike human operatives, the machines have fewer weight restrictions and no issues with undertaking repetitive movements. They can work on multiple lines and pack items in specific patterns.

Inspection

Advanced vision systems can identify faulty or substandard items and separate them from the remaining products, ensuring only those meeting the required standard are packed and delivered to the customer.

Sorting

Parts or packages can be sorted in several ways including using vision systems, scales or numerically. Multiple items can be separated into categories to be used further along the production line or packed for onward transportation.

Benefits of using pick and place robots

There are many benefits to incorporating a pick and place robot or palletiser in your manufacturing operation. One of the main advantages is the significant increase in speed, which allows you to triple or even quadruple your production.

Speed isn’t the only consideration. Pick and place machines also improve the quality and consistency of your products and the safety of your operation. Without the need to work long hours or carry heavy items, employees are less likely to suffer from manual handling injuries or the effects of carrying out repetitive and monotonous tasks.

To find out more about adding a pick and place machine to your operation, contact us today.