Sack-filling machines are a popular addition to manufacturing operations due to their ability to improve efficiency and productivity. By filling bags and sacks automatically, throughput is faster, products are more consistent, and there is less waste.

But all sack-filling machines are not the same and, in this blog, we look at two of the most popular types, VFFS (Vertical Form Fill Seal) and pre-made sack filling, and examine the advantages of each.

What is a sack-filling machine?

A sack-filling machine does what it says on the tin: it fills sacks or bags. Different machines do this in different ways depending on the type of material being used, how the bag is being sealed and what’s inside it.

Regardless of these variables, however, there are always three key steps to filling a bag:

- Preparing the bag

- Filling the bag

- Removing the bag ready for onward storage or transportation

Now let’s look at how some of the machines we supply tackle these steps.

VFFS sack-filling machines

A Vertical Form, Fill, Seal machine makes, fills and seals bags all on the same machine. This makes them extremely efficient – up to 1,500 bags can be made and filled every hour and the operation can be left unattended, allowing thousands of bags to be made and filled automatically.

The bags are made from a flat sheet of plastic which is shaped to create the required size packages. Plastic film is wrapped around a forming tube which heats up and seals the plastic at the back of the bag. Product is then dispensed into the bag, after which heat is used again to seal the top of that bag and the bottom of the next one at the same time.

This method means the bags can only be made from a material which can be heat sealed, such as polythene or paper with a plastic coating inside, and therefore they’re not suitable for all products. Powders such as concrete or flour need to be in breathable packaging, otherwise they’ll react to any moisture present and set, and some foodstuffs which need to be airtight can’t be packaged using a VFFS machine because the gas used to expel the air isn’t compliant with all foods. It’s also more difficult to recycle these types of bags.

Nevertheless, VFFS is especially popular for smaller bags of 1 – 25kg, containing dry snacks, aggregates, pet food and other non-reactive goods.

Pre-made sack-filling machines

Pre-made sack-filling machines use pre-made bags which are picked from a magazine using a vacuum. This means the bags can be any material the vacuum can lift, but are commonly paper, making them easily recycled.

There are two main types of bags:

- Open mouth sacks

These are automatically stitched or sealed closed when full.

- Valve sacks

These are filled via a valve formed into the bag, at the point of manufacture, which is sealed when the bag is full, making the package airtight.

Pre-made bags are not only a better choice for certain products and the planet, as discussed earlier, but can use their existing bags, which already have their original artwork, without the need for any changes or new stock of bags needed. Whilst VFFS bags can be printed, but in doing so, can almost double the price of clear polythene, making it an expensive option.

The Futura range of sack fillers, from Technipes can handle pre-made bags of 10 – 50kg and fill up to 600 bags per hour.

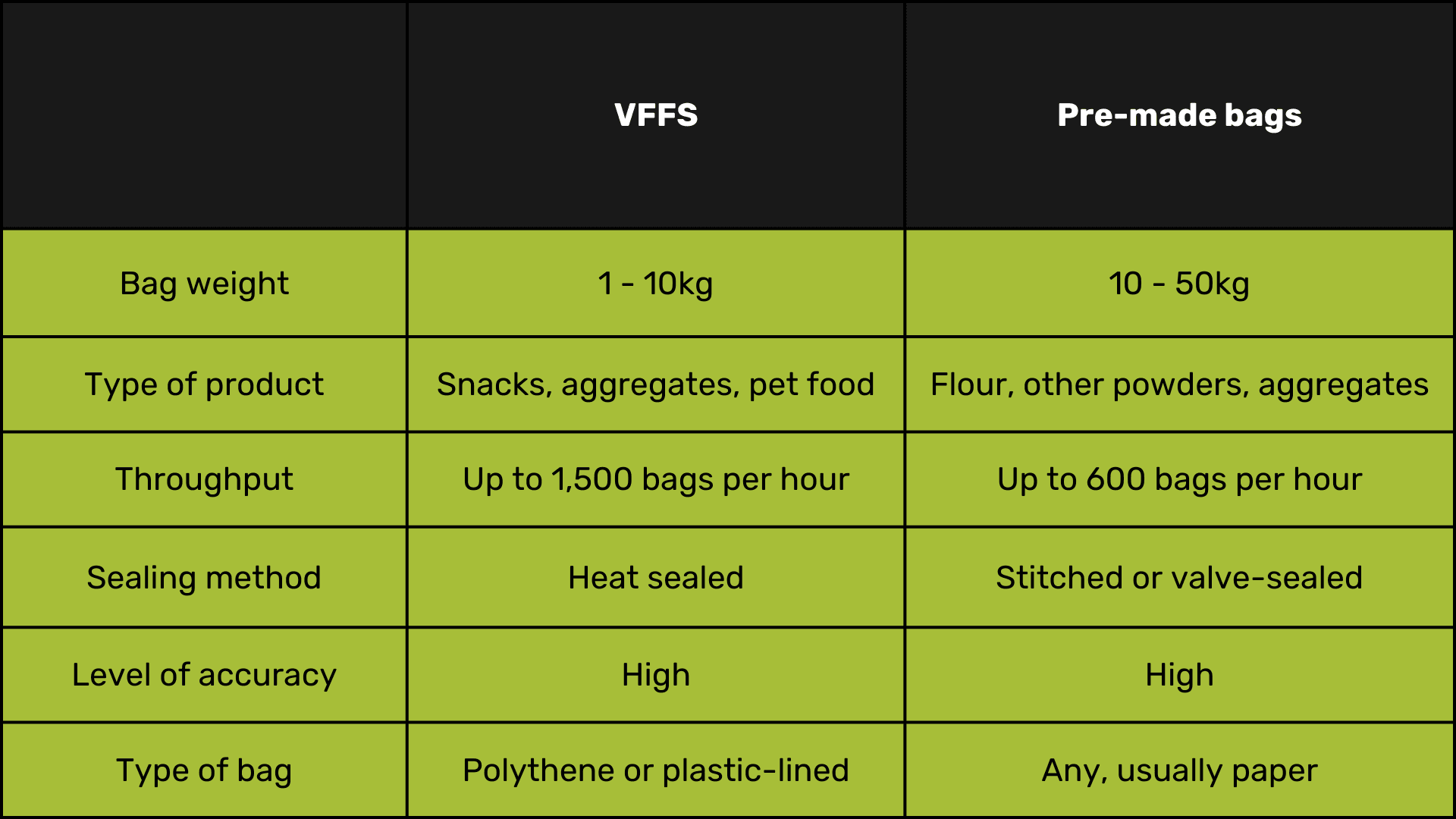

Comparison of the VFFS and pre-made sack-filling machines

How to choose a sack-filling machine

Both VFFS and pre-made sack-filling machines bring advantages and each has its place on the factory shopfloor – it can even be possible to have both, used for different products.

Whether throughput, weight capacity or bag material is the primary factor, we can work with you to find the right machine to meet your needs and ensure installation is smooth and hassle-free.