Europack is a leading supplier of automatic palletising systems, but what makes this company so successful, and why are its products in demand? In this blog, we look at how robot palletisers are helping businesses to improve their end-of-line processes.

Introducing global manufacturer, Europack

Europack designs and builds robots that automate some of the processes that come at the end of the production line, like packaging and palletising. What began in Italy in 1998 is now a global undertaking, and the company operates in over 50 countries.

With over 20 years’ experience in the industry, and an unwavering commitment to research and development, Europack has set itself apart from its competitors.

The technicians behind Europack are responsible for inventing the world’s first rotating beam palletiser (a robot palletiser that works along four axes). Since its launch, other companies have attempted to copy the design, but none have managed to achieve the same thing.

What is a palletiser, and how does it work?

A robot palletiser is a machine that picks up goods and stacks them on a pallet, using a pre-determined pattern of movements.

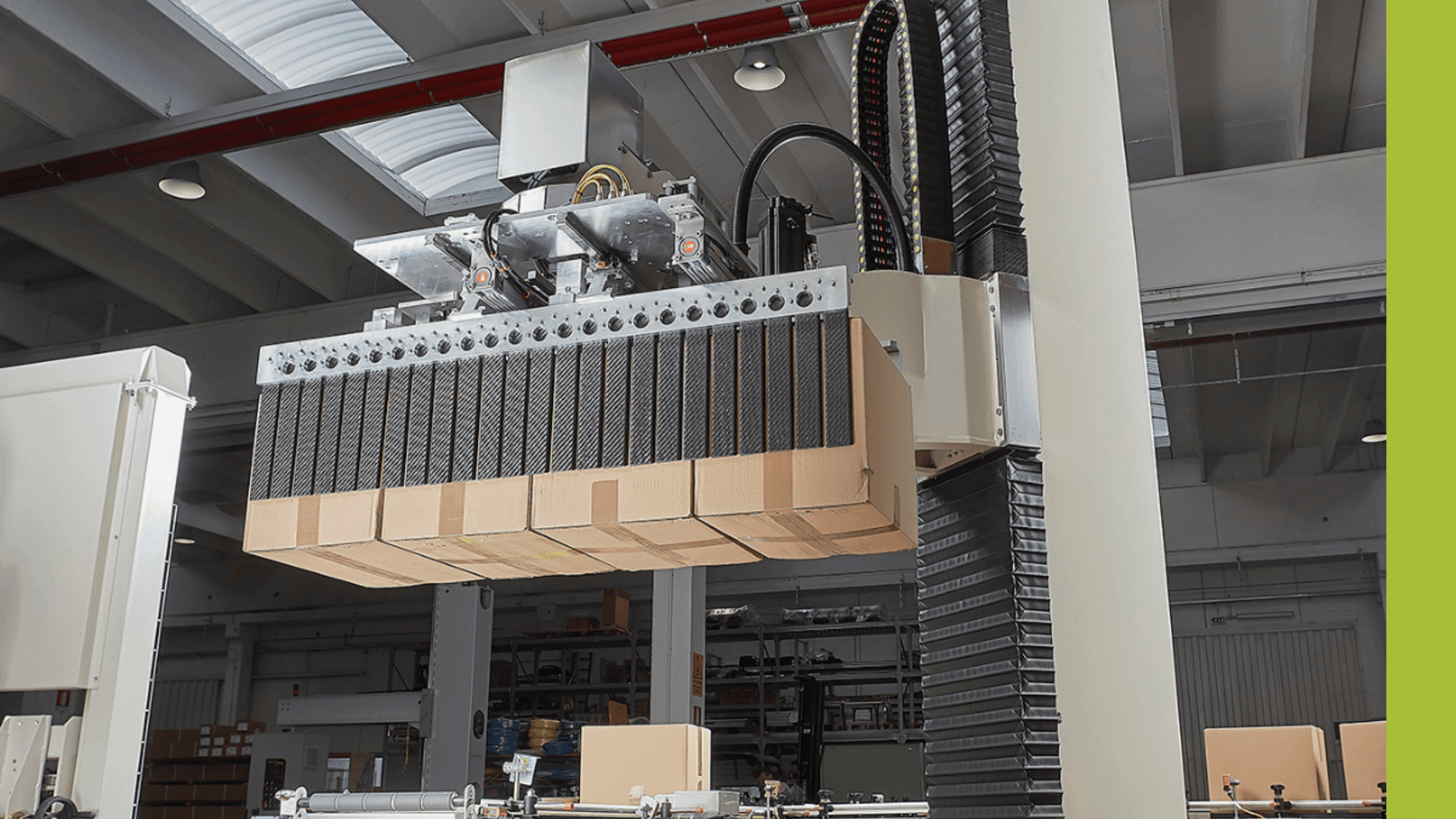

It’s made up of a mechanical arm and a gripping head that moves between the platform and the pallet. Often it’s connected to an automatic handling system (like a conveyor) which brings the goods to the area where they will be picked for stacking.

Europack’s range of robot palletisers

Europack’s robot palletisers have a 360° rotating gripper head that can be changed to suit different products from cans to boxes, packages, coils, bags, and bundles. They also have combined heads that can deal with more than one type of product.

With four servo-controlled axes, Europack’s palletisers can work simultaneously across two production lines to achieve more in the same amount of time.The table below shows the cycles per hour that each product range can achieve.

| Product range | Cycles per hour |

| Winner / ER | up to 480 |

| Winner Green | up to 600 |

| Scara Green | up to 720 |

| Master 250 | up to 400 |

The ‘Green’ range of palletisers uses the kinetic energy produced by the machine to power the robot, in much the same way as a hybrid car works.

Europack call this a kinetic energy recovery system (or KERS for short) and it cuts down on how much electricity is required to run its machines. In fact, the company estimates that its ‘green’ robot palletisers use 70% less power than those that don’t use this system.

You can also buy accessories to work with Europack’s robot palletisers, including:

- an empty pallet store dispenser

- an empty pallet picking-up device

- a device for handling interlayers

All of these accessories limit the amount of human interaction that is needed towards the end of the production line, and speed-up the process.

Why invest in end-of-line technologies?

When you automate production processes, like palletising, your output will increase.

Robotic palletisers are quicker at stacking pallets than humans, and they’re also more effective. They can handle heavy loads without injury, and they can easily reach up to two metres in height to create a more stable pallet.

Not only is this hard to replicate by hand, but it also saves putting unnecessary strain on manual workers, and it frees up their time to be used elsewhere in the business.Europack’s robot palletisers are designed to fit the plant layout and product typology of different customers. For an impartial view on what this might look like for your business, contact PALpack.