The adoption of effective automation has become a game-changer for manufacturers looking to work more effectively. As technology has developed, so tools have evolved that allow tasks to be carried out faster, with greater precision and less risk – helping companies to improve product quality and create safer work environments.

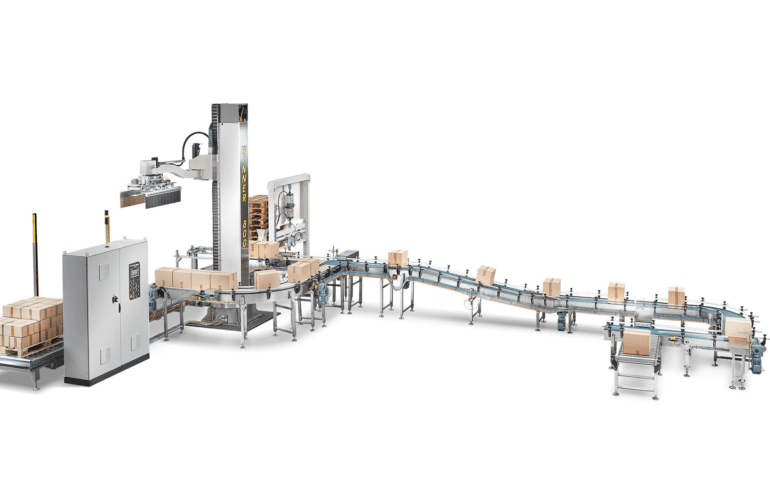

Integrating automated systems such as palletisers, de-palletisers and sack-filling machines not only streamlines operations but provides a wide range of other benefits that allow businesses to stay ahead of the competition.

1. Increased efficiency

The use of robots can bring unprecedented levels of efficiency to manufacturing operations. They significantly reduce manual labour and associated time-consuming tasks, working tirelessly and consistently regardless of the nature of the job or the time of day. Materials are handled swiftly and accurately throughout the entire production line 24/7, significantly increasing throughput and reducing downtime and speeding up the overall manufacturing process as a result.

When automated systems are installed to handle the more physically demanding tasks, this also allows human workers to be assigned to more strategic roles that require critical thinking, problem-solving and decision-making skills. As well as improving job satisfaction, this enables businesses to focus on making improvements to processes and invest in innovation – thus further improving efficiency.

2. More consistency

Quality control is essential in manufacturing, and choosing the right automated system plays a crucial role in ensuring consistent product quality.

For example:

- Palletisers carefully stack products according to predefined patterns, ensuring uniformity and stability.

- De-palletisers automate the unloading of materials from pallets, preventing damage to the product and its packaging.

- Sack-filling machines fill and seal bags with precision and accuracy, eliminating variations in weight and sealing quality.

Following precise instructions and parameters in this way minimises the risk of human error and variations in production. This means products have consistent specifications, measurements and tolerances so customers’ expectations are met every time and brand reputation is maintained.

3. Fewer injuries

A safer working environment brings a number of benefits: less downtime due to illness or injury, a more motivated workforce and a better safety record for the company as a whole, and automation has a big part to play in achieving this goal.

Automating repetitive and physically demanding tasks, such as palletising and de-palletising reduces the likelihood of manual handling injuries, as well as incidents caused by human error due to fatigue.

Transforming operations

By investing in automated systems such as palletisers, de-palletisers, and sack filling machines, businesses can unlock their full potential and transform their manufacturing processes.

Integrating robots into a production line brings a range of benefits, from helping to meet customer demands promptly to maintaining product quality, all of which help a business to gain a competitive edge and maximise profitability.