As manufacturers strive to maintain competitive advantage, many are investing in automation as a way of streamlining production and making it more cost-effective.

But adding robotics into a production line doesn’t just improve efficiency, it brings other benefits too, by creating a safer work environment and reducing workplace injuries.

1. Reducing manual handling injuries

One of the primary benefits of automation is that it can take over the most physically demanding tasks of heavy lifting and repetitive motions. These put individuals at risk of developing manual handling injuries such as musculoskeletal disorders, back pain or repetitive stress injuries which not only cause pain and suffering for workers but can result in decreased productivity and higher costs for employers.

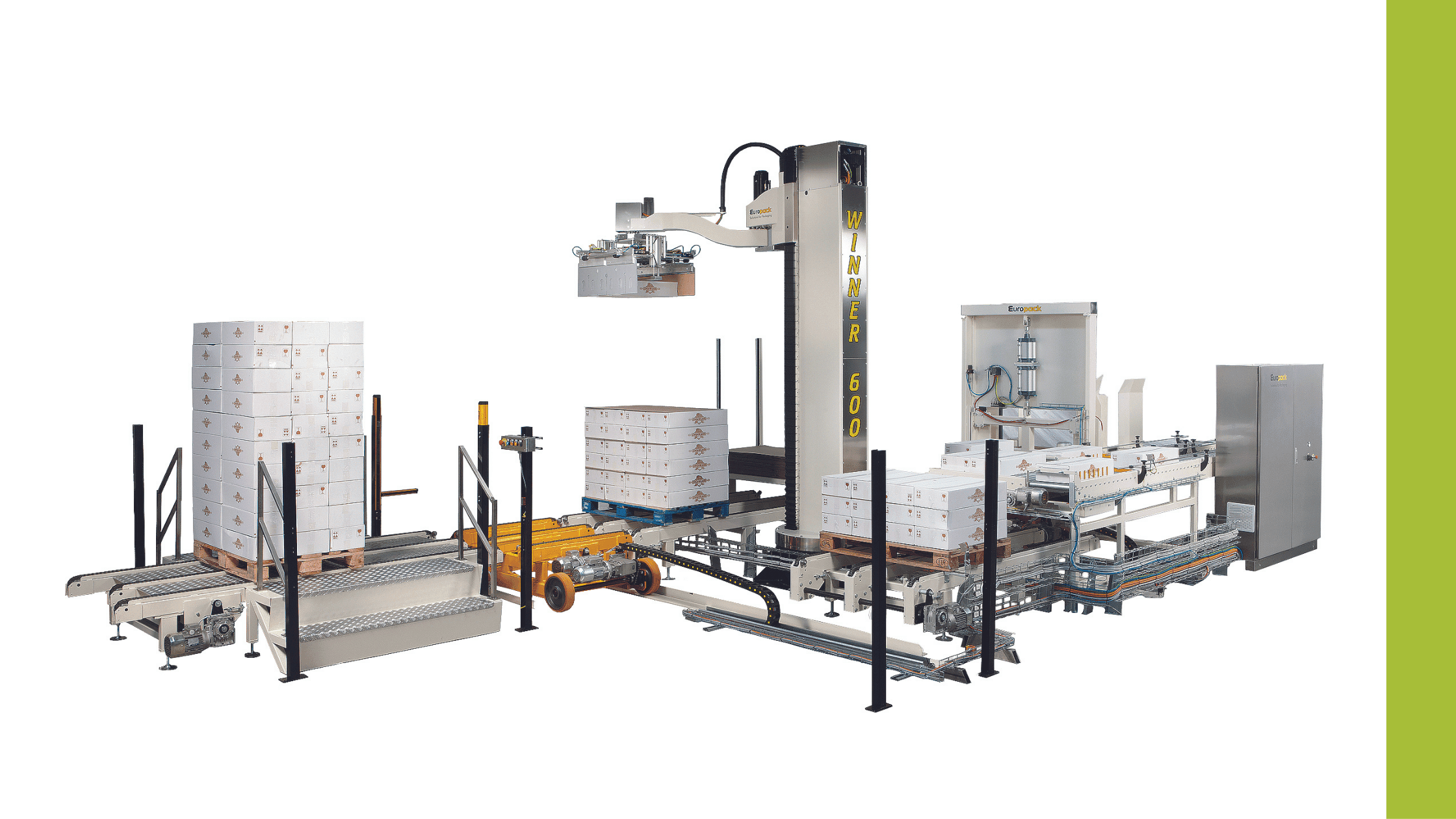

One such job is palletising, the time-consuming, labour-intensive and often monotonous job of sorting, transferring and stacking goods onto a pallet. Automatic palletisers make the process quicker and safer by handling heavy or awkwardly-shaped packs that can be difficult for an individual to move. Europack’s range of palletisers can be supplied with picking-up heads for bags, boxes, cans, reels and bundles, so they can handle a wide range of packages of all sizes with ease.

Many automated systems can also be designed with ergonomic features such as adjustable height and easy-to-use controls, which can help to reduce physical strain on workers and improve the overall comfort of the work environment.

2. Preventing workplace accidents

It goes without saying that when fewer workers are required, fewer people are exposed to the hazards of the production line. This, in turn, leads to a decrease in the number of workplace accidents, as well as a reduction in the severity of accidents that do occur.

Automated machines can also perform tasks faster and more consistently than human workers, which can not only reduce the risk of fatigue and boredom-related accidents but leaves less room for human error, which can often lead to accidents and injuries.

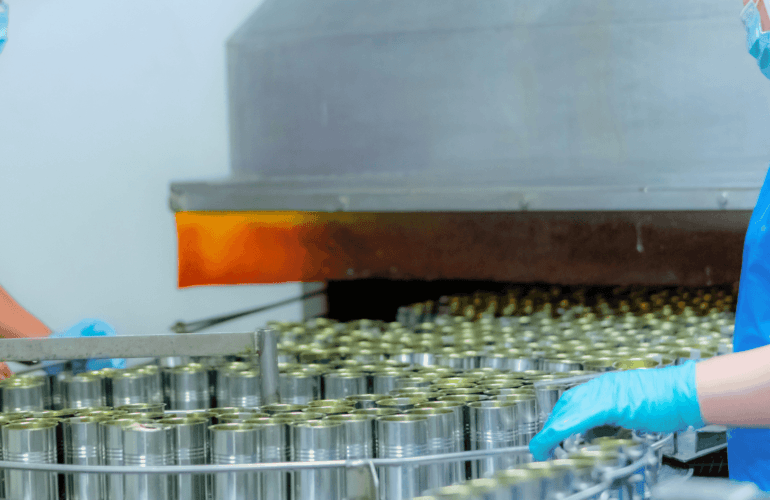

Sack-filling machines bag grains, pellets and aggregates, sealing them in medium to large sacks ready for palletising and transportation. The technology means that what would take several people minutes to complete can be accomplished in just a few seconds, with far greater precision and accuracy.

3. Improving employee wellbeing

Automation can also lead to increased employee morale and contentment. When employees are not exposed to monotonous or physically demanding tasks, they are more likely to feel safe and secure in their work environment, to be more motivated and to have higher levels of job satisfaction. Not only does this help to reduce the risk of accidents and injuries in the workplace, but it also improves mental health and wellbeing overall.

Investing in safety

It’s important to note that machines alone cannot reverse a poor safety record or create a healthy and safety-conscious culture. Companies must properly train workers on how to operate and maintain automated systems and regularly assess the safety of their processes to ensure that they are functioning correctly.

However, with those processes in place, automating manufacturing processes has the potential to greatly reduce the number of workplace injuries and create a safer work environment for all employees.