The growth of robotics is bringing automation within reach of more and more businesses. As technology advances and costs drop, firms of all sizes are finding that robots are an accessible and affordable option that can bring real benefits to their operations.

But with the wide range of machinery now available, how do you choose the best robotic palletiser, sack-filling machine or handling system for your business? In this blog, we’ll look at what you should consider to ensure your investment in robotics pays off.

Why consider automation?

There are few operations that can’t benefit from some element of automation. Whether it’s filling sacks, loading pallets or picking packages, automating these processes allows them to be carried out more consistently and efficiently, ultimately improving productivity and reducing costs.

How to choose the right robots for your business

If you’ve decided that investing in automation could benefit your business then the next step is to work out what type of machinery is going to add the most value.

To do this, you need to map out your current processes. Make sure this is as detailed as possible, so you can identify any sticking points or bottlenecks in the production line. Think about what you want to achieve and remember that productivity isn’t the only consideration here.

Before making an investment you also need to think about:

Payload

This ensures the robots you’re considering are fit for purpose. Gantry or cartesian palletisers can be configured to carry bags weighing hundreds of pounds but not all robots can manage the same type or weight of packages, so make sure you’re clear on what the machinery will be handling.

Speed

While one of the benefits of automation is increased efficiency, not all applications need to be completed at high speed. Layer palletisers have a production speed of up to 60 packs per minute but if your outputs are lower, a simple pick and place machine may be sufficient.

Available space

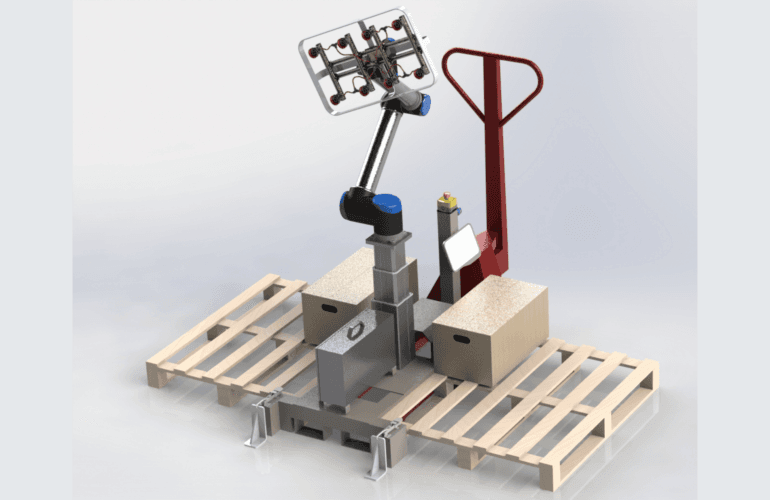

Think about the layout of your production line as well as available floor space. Palletising systems can be designed to fit a specific area, so you can make the most efficient use of the allocated space – and where floorspace is particularly limited a robotic palletiser could be a good option.

Installation

Some systems can be integrated into your operations much more quickly and easily than others. Consider if there will be any downtime while the installation takes place and factor the cost of this into any quotes.

Bespoke solutions

Are you buying an off-the-shelf solution or is there scope to customise your machinery to meet specific needs? If you have particular requirements then talk to your automation supplier about how these can be met. If you are going to have automation designed for you, you’ll need to compile a good User Requirements Specification (URS) to detail exactly what you need.

Maintenance

Unscheduled downtime is costly and inconvenient. Do your research into the reliability and after-sales service of your robotics manufacturer to make sure that you’ll have support if or when you need it.

Finding a robotics supplier

As well as choosing the right machinery, you also need to choose a supplier that you can trust to deliver. Ultimately, finding someone who is the right fit for your business comes down to having shared goals and values but you should also ask for testimonials and case studies that can demonstrate their experience.