From layer palletisers to cartesian palletisers, in the competitive world of manufacturing an automatic palletiser is a valuable addition to a production line.

But what is a palletiser? What does a palletiser do and why is it such a beneficial piece of equipment?

In this blog, we take a closer look at the features and benefits of palletisers, delve into the different types and provide an overview of the brands available.

What does a palletiser do?

An automatic palletiser is a machine that sorts, transfers and stacks products onto a pallet ready for shipping or storage, usually at the end of a manufacturing line.

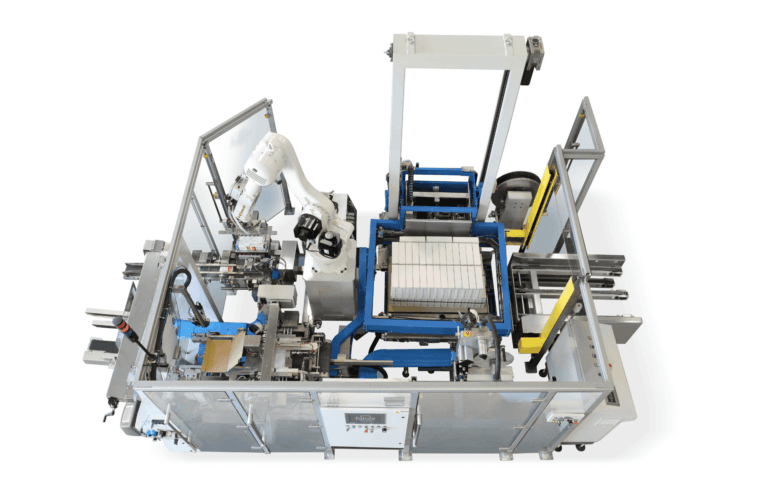

Depending on the type of palletiser, robotic arms or other mechanisms are used to place the products onto the pallet, either in bulk or one-by-one. Different gripper heads can be attached, allowing a wide range of different items to be picked up and moved.

Not only does this make the process of moving and loading products quicker and safer than if it were carried out by hand, but it also provides greater load stability and makes it possible to move more loads at once.

Different types of palletisers

There are three main types of palletisers, and each is best suited to different situations and applications.

- Cartesian, or gantry, palletisers feature a structural beam and axes, which allow packages to be moved in three directions. A gripping device picks and places the items onto the pallet.

Advantages: Because items can be moved in three ways and with head rotation, complex pallet patterns can be created if required.

Limitations: Medium speed and medium output. Up to 26 – 20 packs per minute

Best used for: Heavy items, or complex pallet patterns. - Layer palletisers are designed to move a full layer of boxes or containers onto a pallet at once.

Advantages: Quick and efficient. Because items are collated together rather than picked individually, even heavy and awkward packages that a gripper may struggle to manoeuvre can be moved easily.

Limitations: Unable to accommodate mixed pallets or changeable product sizes and shapes.

Best used for: Higher-speed applications and heavy or awkward packs that are difficult to handle. Up to 60 packs per minute. - Robotic palletisers pick up products using a gripper or other head and transfer them to a pallet.

Advantages: Small footprint and versatility, with the ability to assemble mixed pallets as well as palletising different items simultaneously.

Limitations: Medium speed and low output.

Best used for: Complex pallet patterns, and multiple pallets.

The best palletiser brands

At PALpack, we only supply equipment from manufacturers who we trust. We work with two leaders in their field: Europack and Lita, to bring you the widest possible range suitable for multiple environments and types of products.

Lita specialises in medium to high-speed palletisers including Cartesian palletisers, robot arm palletisers and layer palletisers and is known for its exceptional design and build standards. Established in 1962, it is still a family-owned company with machines installed around the world, in sectors from food to cosmetics.

Europack is a highly respected manufacturer with more than 25 years of experience in the industry and operations in over 50 countries. Committed to research and development, Europack’s technicians invented the first rotating beam palletiser (a robot palletiser that works along four axes) and developed the innovative Kinetic Energy Recovery System (KERS), an energy recovery system similar to that on many hybrid cars which means Europack machines use up to 70% less energy than other robotic palletisers. Europack are also world leaders in sack palletising, one of the most difficult palletising products to handle.

Whichever palletiser you choose, these machines play a pivotal role in enhancing efficiency, reducing costs, and upholding product quality. Installing a palletiser has the potential to redefine your packaging and transport processes, making them faster, more precise, and safer.