The industrial revolution took place from the mid-1700s to the mid 1800s, with the first industrial automation recorded in 1771. How did we go from a water-powered spinning mill to complex, fully automated manufacturing? And how do we get from where we are now to lights-out manufacturing?

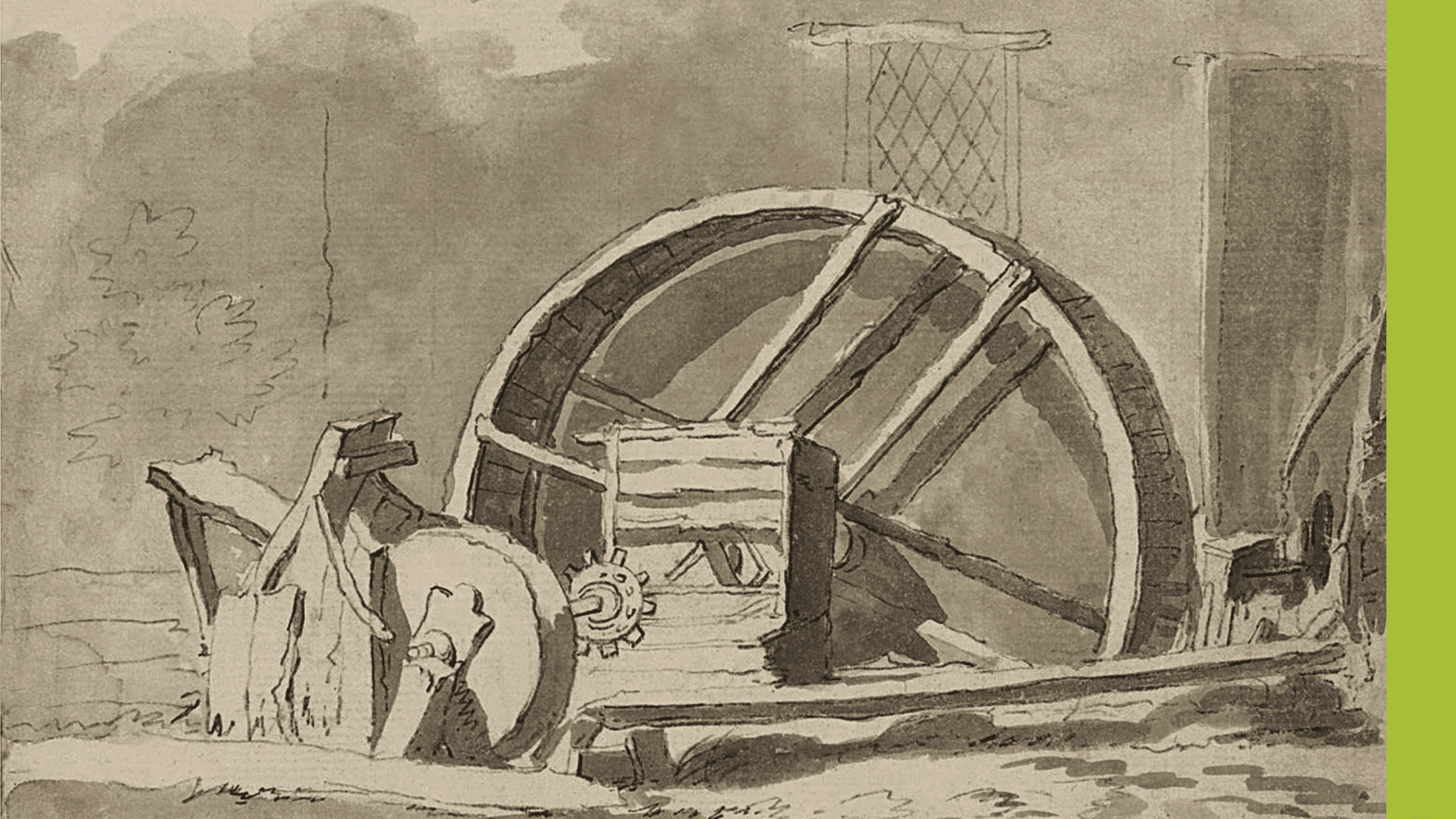

Automation is the use of control systems to operate equipment or machinery without, or with minimal, human intervention. Automation of the manufacturing process is relatively new. Richard Arkwright invented the first fully automated spinning mill in 1771, driven by water power, and Oliver Evans developed an automatic flour mill in the mid-1780s, making it the first completely automated industrial process.

The industrial revolution

Automation developed throughout the industrial revolution to increase factory productivity. The introduction of electricity in the 1920s added a new automation method. Currently, automation can be achieved by means which include mechanical, hydraulic, pneumatic, electrical, electronic or through computers, and more often a combination of these.

The impact of car manufacturing on automation

Technological leaps continued to be made since the 20s, but the term automation wasn’t widely used until 1947, when General Motors set up a department just for this purpose, and car automation has continued to drive a high standard of evolving technology. Car factories in the 1980s were the first step to “lights-out” automation – a vision of a manufacturing process run entirely without the need for any human intervention at all.

Current automation of the manufacturing process

The number of manufacturers using automation technology is growing – global use of robots has doubled over the last five years. As the use grows, so does the accessibility to this kind of technology. Handling systems, AGVs, palletisers and sack filling are all achievable solutions for a manufacturer today, especially with the UK government offering incentives for those who adopt automation machinery.

The future of automation

Despite some concerns about the impact it has on employment, the current pandemic has clearly demonstrated how automation facilitates business continuity. The sector will continue to grow, as new technologies and uses for that technology are developed.

The International Federation of Robots (IFR) often report on collaborative robots, or cobots, which are the robots which work safely alongside humans. Although lights-out automation has yet to be achieved, we grow incrementally closer as technology advances.

Want to chat?

If you’re considering automation for your business, please get in touch with PALpack and speak to an expert for free advice.