Palletisation and depalletisation are two essential operations in the handling of goods and materials. Palletisation refers to the process of placing goods onto a pallet whilst depalletisation is the act of removing them – and both take place in a variety of industries.

The processes may be carried out by hand, but they can be time-consuming and laborious work and as a result, manufacturers are increasingly turning to machines to undertake the tasks. Not only are automatic palletisers and depalletisers faster and more efficient, but they can also move larger and heavier items more safely.

How do palletisers and depalletisers work?

Palletisers and depalletisers are commonly used in material handling and logistics industries and make handling goods in large quantities, such as in distribution centres, warehouses, and manufacturing plants, quick, safe and efficient.

A palletiser stacks and arranges products onto pallets in a specific pattern. Products are placed on a conveyor belt, which moves them towards the palletiser and the palletiser then uses robotic arms or other mechanisms to pick up and place the products onto a pallet in a predetermined configuration. Once the pallet is fully loaded, it is removed by a forklift, pallet jack, or other handling equipment and replaced with an empty one before the process begins again.

On the other hand, a depalletiser is a machine that is used to unload products from pallets. Using a forklift or other material handling equipment a pallet is placed onto a conveyor, which moves it towards the depalletiser. The depalletiser then separates the goods from the pallet and places them onto another conveyor, singulated and then moved further along the production line.

Choosing a palletiser or depalletiser

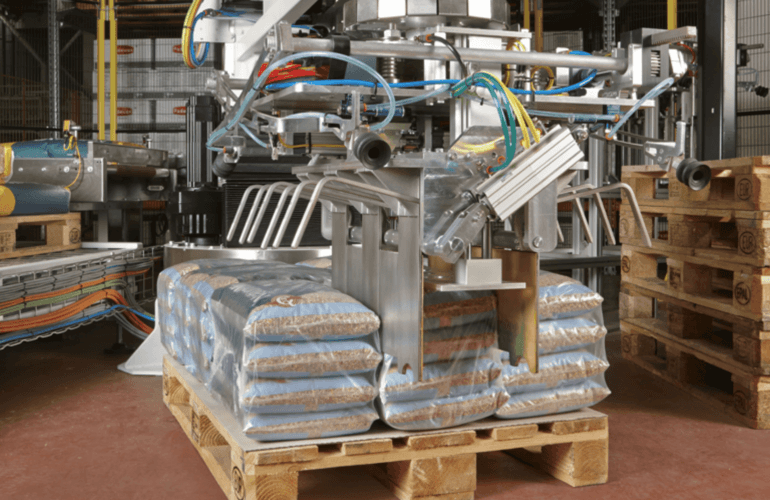

Both palletisers and depalletisers can be designed to handle different types of products, such as boxes, bags, cartons, and cans, among others. They can also be configured to work with different types of pallets, such as wood, plastic, or metal.

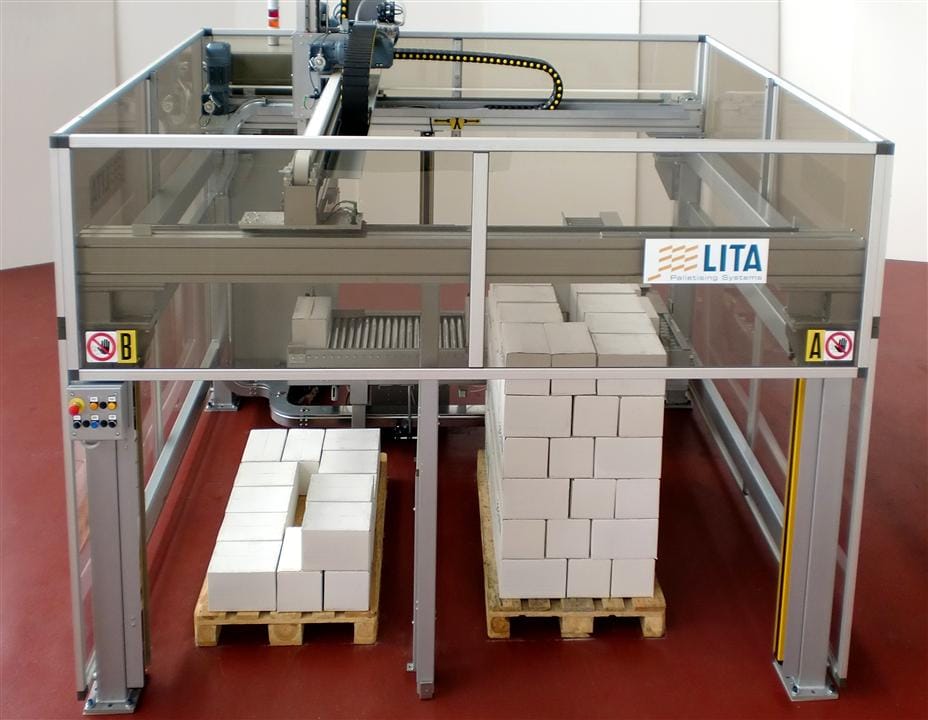

At PALpack, we work with leading manufacturers Europack and Lita to offer you the widest range of automatic palletisers and depalletisers. Each is engineered to suit different products and environments and accommodate different production speeds and existing lines.

There are three main types of machines available:

- Cartesian or Gantry Palletisers and depalletisers are characterised by their structural beams and axes, which are used in conjunction with grippers to move products in three directions, enabling complex pallet patterns. Though they are typically low-medium speed they are highly flexible and have lower implementation costs.

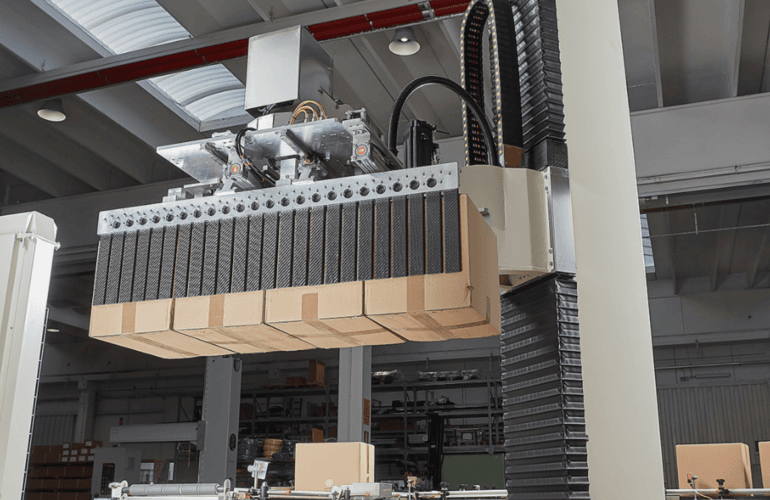

- Layer palletisers and depalletisers are designed to load or remove a whole layer of a pallet at a time. They can be programmed according to your specific needs and are ideal for higher-speed applications and heavy or awkward packs that are difficult to handle. They have a larger output of up to 60 packs per minute.

- Rotating beam palletisers have a relatively small footprint and are ideal for small spaces. Invented and manufactured by Europack, they are incredibly versatile; the same machine can be used to collect pallets, collect layer cards and have multiple lines feeding into the same machine. However, like the pick and place machines, they also have a slow speed and low output.

Palletisation and depalletisation are important operations in the handling of goods and the use of palletisers and depalletisers can significantly improve the efficiency and productivity of material handling operations. Businesses that recognise this and invest accordingly can reduce the risk of injury to workers, increase throughput and minimise product damage – saving time and money in the long term.